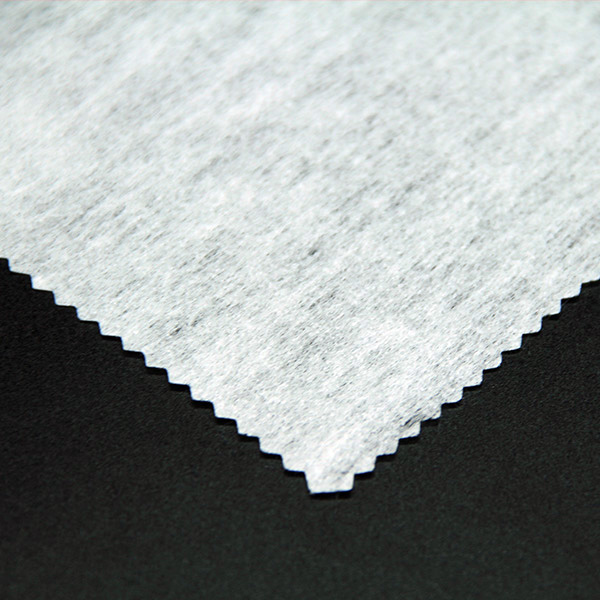

Interlining Paper Definition:

Solf Impregnated Non-Woven Interlining Fusing Paper is a soft feel, excellent performance, and is widely used in various types of light garment interlining products. Generally, it is made of PET polyester chemical fiber, and in addition to the bonding chemical, a softener is added to adjust the feel. interlining paper is made by bonding the combed fiber web through the impregnation tank, and then it is processed into soft feeling coated interlining fabric through the subsequent drying and powdering and hot pressing process.

Detailed Product Specifications and Parameters:

Detailed specifications: 100% PET polyester staple fiber, generally coated with LDPE rubber powder.

| Composition: | 100% polyester |

| Grammage range: | 23-100gsm |

| Width range: | 90-210cm |

| Color: | Black/white |

| Order quantity: | 15000M |

| Feel hardness: | Soft |

| Packing quantity: | 100Y or according to customers' requirements |

| Packaging material: | PE transparent tape |

| Loading quantity: | 4.5T/20ft container |

| Customs code: | Above 70g 56039390, below 70g 56039290 |

| Glue powder: |

LDPE is generally used. PES, HDPE optional. |

| Pressing temperature: |

115-125 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: |

12-15S |

Product Features:

The most important feature of Impregnated Non-Woven Interlining Fusing Paper is the adjustment of the working fluid. The characteristics of the product can be realized in the working fluid without the need to add additional processes to the finished fabric. In the working fluid, the common characteristics can be adjusted: soft and hard, waterproof, dyeing, water absorption, flame retardant, etc. At the same time, different rubber powder coatings can be chosen according to customer needs. Because of its light texture, soft hand feel, stable grammage, wide width range, easy bonding, and low cost, it is loved by overseas customers.

Certificate of Non Woven Interlining

Introduction To The Production Process:

Feeding cotton (polyester staple fiber) ---Opening and loosening --- Pre-carding --- Laying web forming --- Main carding --- Impregnation (the chemical fiber in the web is soaked with glue) --- Pressing roll (the press roll makes the nonwoven fabric form) --Drying in barrel --Reeling --Separating --Packing

Product Application Description:

You May Also Like:

|

|

|

| Soft Handfeel Foaming Impregnated Non-Woven Fabric | Hard Handfeel Foaming Impregnated Non-Woven Fabric | Hard LDPE Glue Impregnated Non Woven Interlining Paper |