Interlining Paper Definition

Impregnated Non Woven Interlining Paper is a cost-effective, high-performance interlining product that is widely used in various apparel industries. Generally, it is made of PET polyester chemical fiber, using chemical reagents (usually adhesives and hardening reagents), bonding the carded fiber web through the impregnation tank, and then processing it into a hard feeling coated interlining fabric through subsequent drying and powdering and hot pressing processes.

Detailed Product Specifications And Parameters:

Detailed specifications: 100% PET polyester staple fiber, generally coated with LDPE rubber powder.

| Composition: | 100% polyester |

| Grammage range: | 23-100gsm |

| Width range: | 90-210cm |

| Color: | Black/white |

| Order quantity: | 15000M |

| Feel hardness: | Hard |

| Packing quantity: | 100Y or according to customers' requirements |

| Packaging material: | PE transparent tape |

| Loading quantity: | 4.5T/20ft container |

| Customs code: | Above 70g 56039390, below 70g 56039290 |

| Glue powder: |

LDPE is generally used. PES, HDPE optional. |

| Pressing temperature: |

115-125 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: |

12-15S |

Impregnated Non Woven Interlining Paper Features:

Certificate of Non Woven Interlining

Impregnated Non Woven Interlining Paper Process:

Feeding cotton (polyester staple fiber) ---Opening and loosening --- Pre-carding --- Laying web forming --- Main carding --- Impregnation (the chemical fiber in the web is soaked with glue) --- Pressing roll (the press roll makes the nonwoven fabric form) --Drying in barrel --Reeling --Separating --Packing

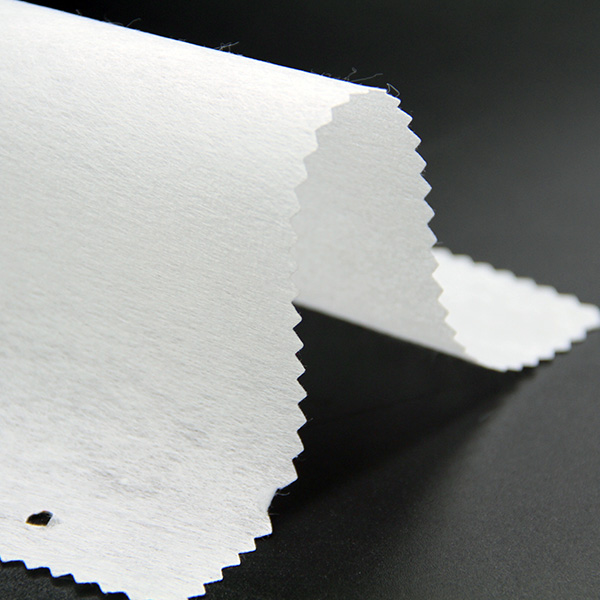

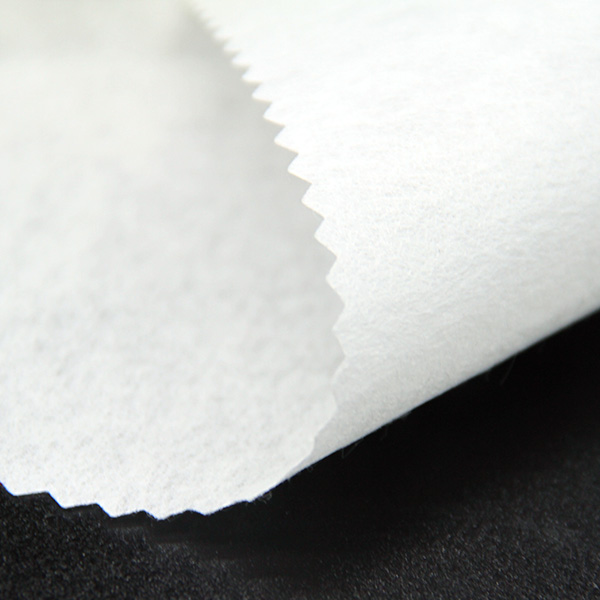

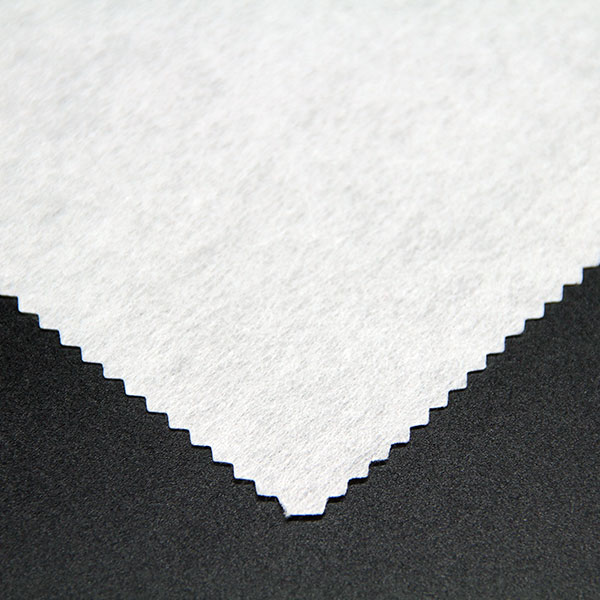

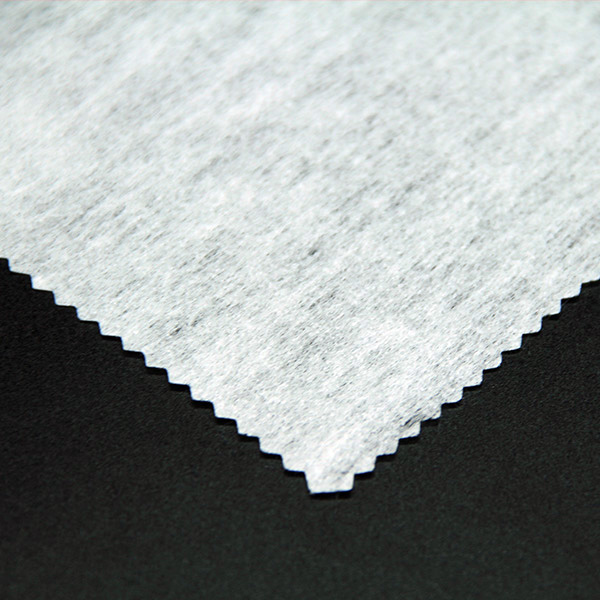

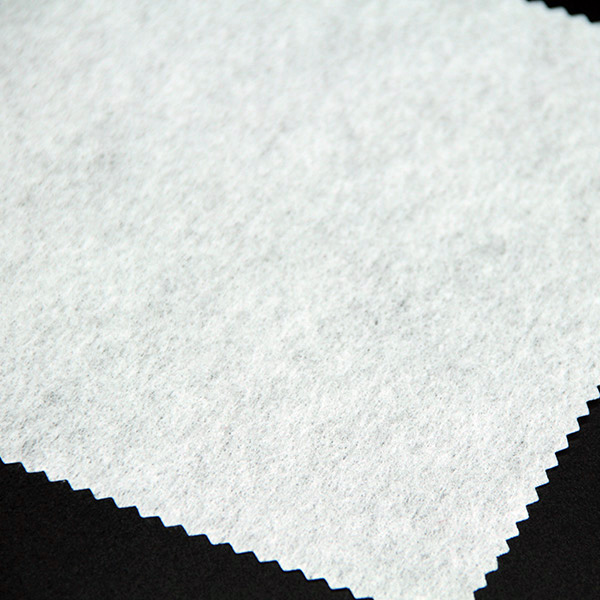

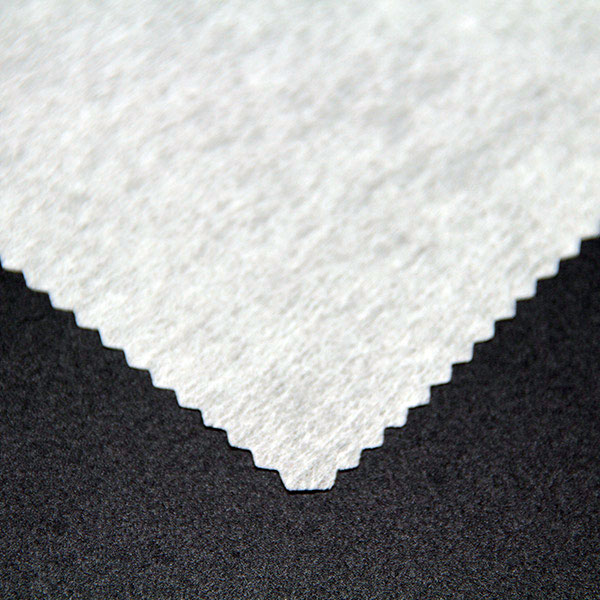

Product Picture Show

Product Application Description:

Impregnated Non Woven Interlining Paper Basic function. To make the garment as a whole straight, with clear and straight folded edges, to achieve the ideal design requirements. Maintain the good structural form and stable size of the garment. To improve and enhance the processing performance of garment fabrics and their wrinkle resistance and strength. Improve the warmth of the garment and make the garment strong and wearable.

You May Also Like:

|

|

|

| Soft Handfeel Foaming Impregnated Non-Woven Fabric | Hard Handfeel Foaming Impregnated Non-Woven Fabric | Soft Handfeel Chemical Bonded Nonwoven Fabric |