Definition:

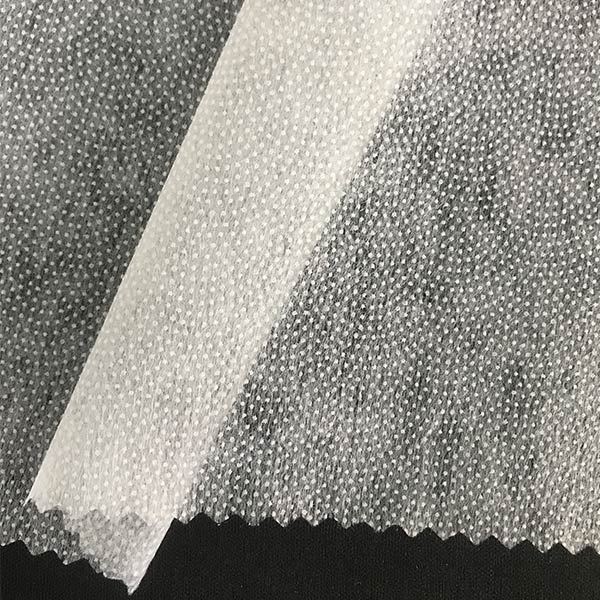

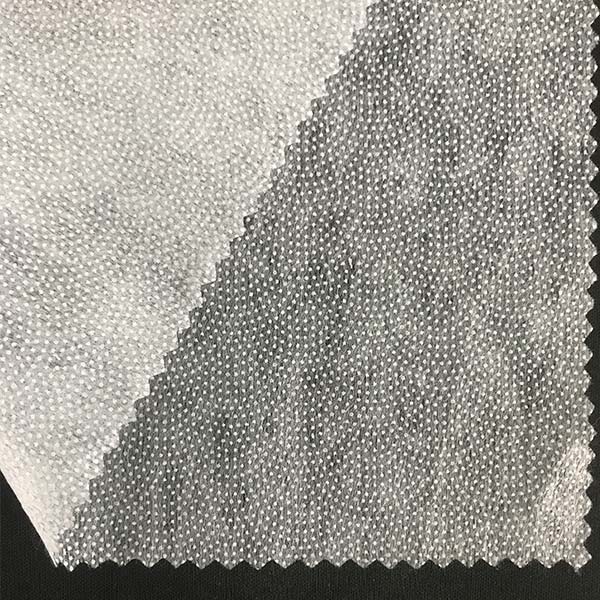

Nonwoven dot paste fusible interlining is an interlining fabric made of polyester hot-rolled nonwoven fabric with special processing techniques such as PES adhesive powder coating and finishing.

Detailed Product Specifications And Parameters:

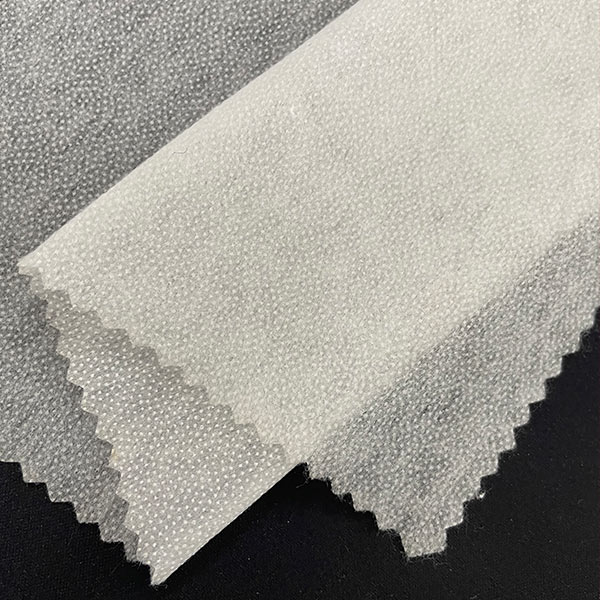

Detailed specifications: General 25G backing on 8G glue powder, using PES slurry dot coating process.

| Composition: | 100% polyester chemical fiber |

| Grammage range: | Base fabric: 25G; Coating: 8G |

| Width range: | Within 2 meters |

| Color: | White, black, grey, extra white |

| MOQ: |

5000m |

| Feel hardness: | Regular feel |

| Packing quantity: | According to customer requirements |

| Packing material: | PE transparent plastic bag |

| Loading quantity: | 20GT/40HQ |

| Customs code: | 5603911090; 5603921090; 5603931090. |

| Glue powder: |

PES |

| Pressing temperature: |

120-130 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: | 12-15S |

Features:

Using conventional 25G hot-rolled non-woven fabric as the backing, generally on 8G coated rubber powder, also can provide different gram weight and width according to customer requirements.

No need to add chemical additives in the production process, the product is environmentally friendly and free of odor and harmful substances.

Standard weight in terms of softness, thickness, etc., suitable for all kinds of garment lining.

Non-woven dot pastes fusible interlining cost-effective, strong adhesive force, easy to produce bonding.

PES rubber powder has good washing resistance, non-fluorescent, dry cleaning, light enzyme washing resistance, etc.

Certificate of Non Woven Interlining

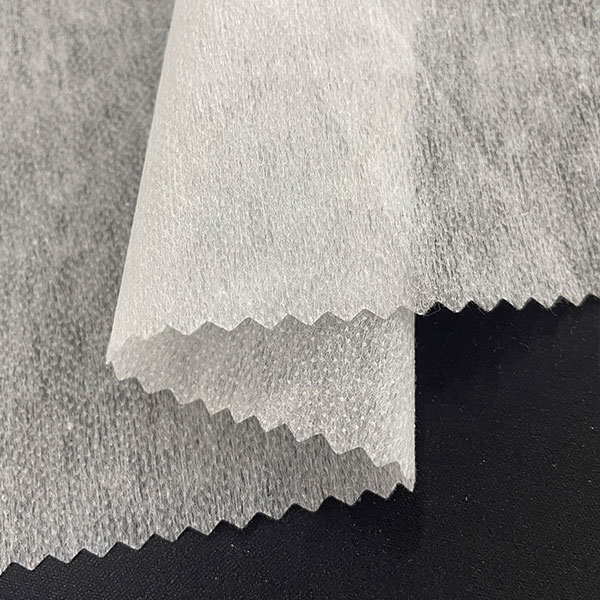

Introduction To The Production Process Of Backing Fabric:

Polyester staple fiber, or and other fibers through the open cotton process to fully break up the fiber, mixed, and then after carding, laying the net, by hot rolling stick hot rolled into shape to complete the production of Nonwoven dot paste fusible interlining.

Introduction To The Slurry Point Coating Process:

The PES slurry dot method is to mix a certain particle size of PES hot-melt adhesive powder with water thickener etc. according to certain formula and process to make a stable slurry with certain viscosity first. Then, drawing on the circular screen printing process, the paste containing hot melt adhesive is transferred to the base fabric in the form of dots under the pressure of the squeegee through the inner holes of the finely designed circular screen. Finally, the hot melt glue is melted and cooled by evaporating water in the drying room, and then packed in rolls.

Product Picture Show

Application Description:

Product weight, moderate thickness, a wide range of applications, nonwoven dot paste fusible interlining suitable for all kinds of light or medium thickness fashion, as well as garments of various specific parts. Production process without chemical additives, suitable for all kinds of products with high requirements for environmental protection.

You May Also Like:

|

|

|

| C7018 Microdot Non Woven Fusible Interlining | 6140W Enzyme Wash Non Woven Fusible Interlining | AC5525 Nonwoven Fusible Interlining |