Definition:

Enzyme wash non-woven fusible interlining is based on the need for enzyme wash for some garments. Based on the ordinary double dot nonwoven fusible interlining, high-quality gum powder and chemical additives are used to make the interlining and fabric bonding fastness stronger, which can meet the requirements of higher temperature water washing and enzyme wash.

Detailed Product Specifications and Parameters:

Enzyme washes nonwoven fusible interlining detailed specifications: Generally, it adopts PA double dot coating on the gluing process, high quality 10G glue powder on 25G backing, high-temperature resistant washing, and enzyme washing.

| Composition: | 100% polyester chemical fiber |

| Grammage range: | Base fabric: 25G; Coating: 10G |

| Width range: | Within 2 meters |

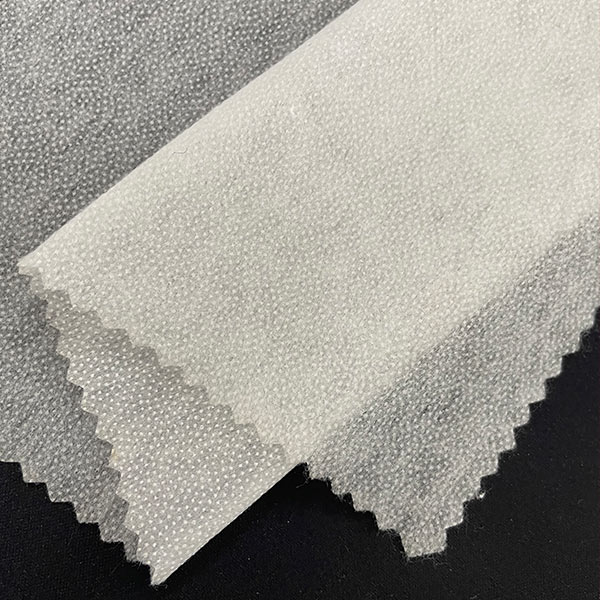

| Color: | White |

| MOQ: | 5000m |

| Feeling hardness: | Regular Feeling |

| Packing quantity: | According to customer requirements |

| Packing material: | PE transparent plastic bag |

| Loading quantity: |

20GT/40HQ |

| Customs code: | 5603911090; 5603921090; 5603931090. |

| Glue powder: | PA |

| Pressing temperature: |

120-130 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: |

12-13S |

Features:

Certificate of Non Woven Interlining

Enzyme Wash Nonwoven Fusible Interlining Process:

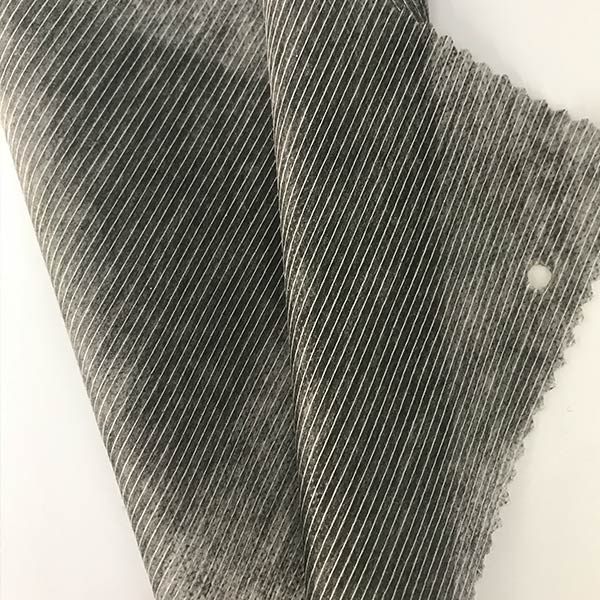

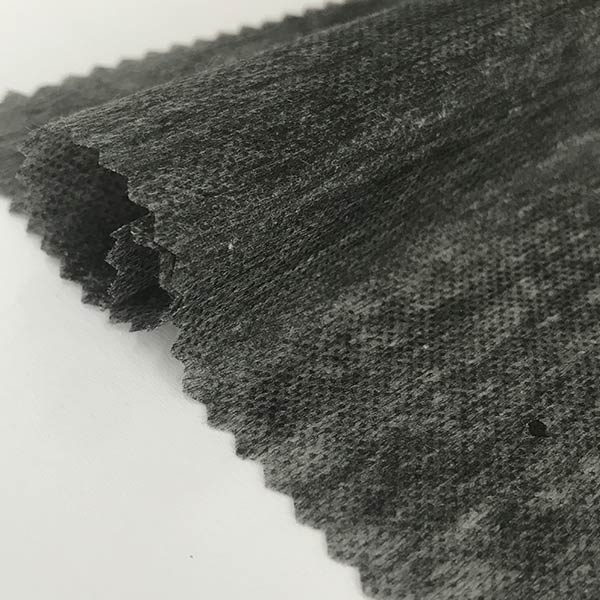

Hot rolling process for the production of backing fabric: The polyester staple fiber or other fibers are fully broken up and mixed by the open cotton process. After combing and spreading, the backing is hot-rolled by hot-rolling sticks to complete the production of backing fabric. Finally, we use PA double dot coating process to coat and glue on the backing fabric.

The dot pattern of double dot coating consists of a lower layer of pulp dot layer and an upper layer of dusting layer, so the height of the double dot coating dot on the upper surface of the backing is generally higher than the height of the pulp dot bump, so there is also a more obvious prickly feeling. The higher dots also allow more fibers to penetrate deeper into the fabric yarn during bonding, resulting in a higher initial peel strength, which can then be packaged in rolls.

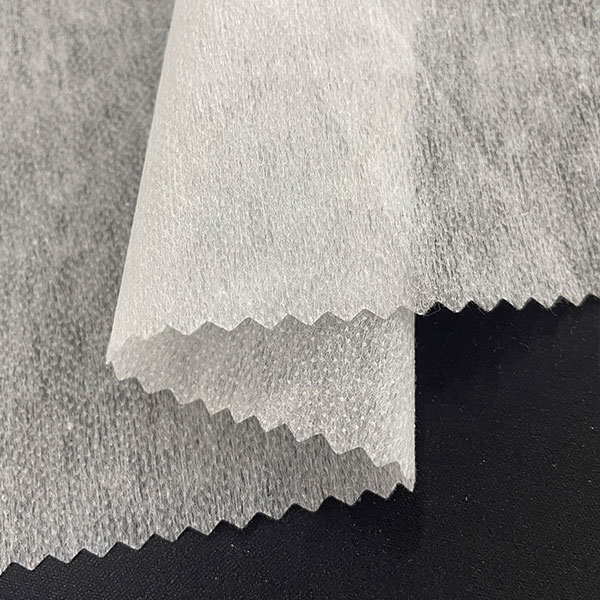

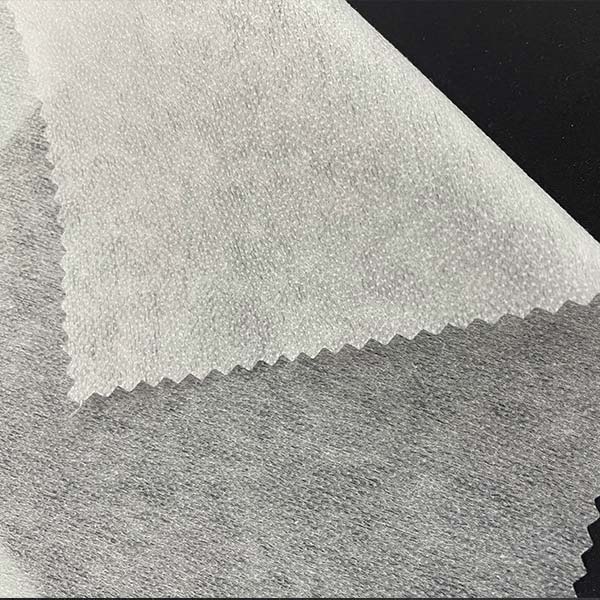

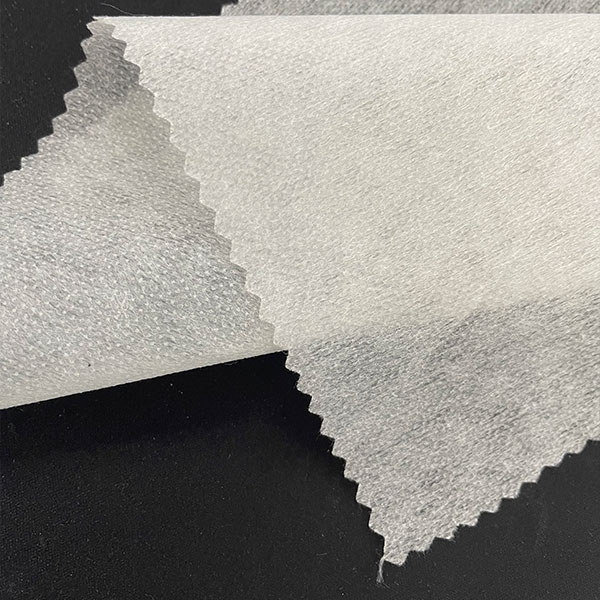

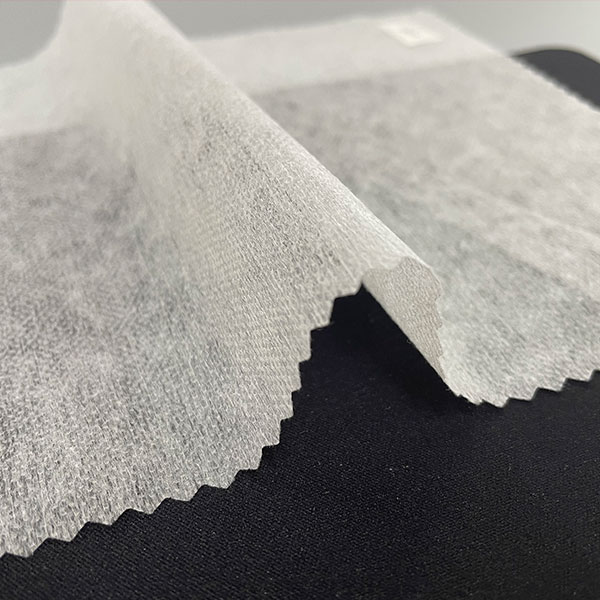

Product Picture Show

Application Description:

Enzyme washes nonwoven fusible interlining with PA double dot coating process, it is suitable for all kinds of light and thin garments that have requirements for high-temperature washing and enzyme washing.

You May Also Like:

|

|

|

| AC5525 Nonwoven Fusible Interlining | QD7025 Non Woven Double Dot Interlining With Quilting Seam | D7025 Double Dot Fusible Interlining |