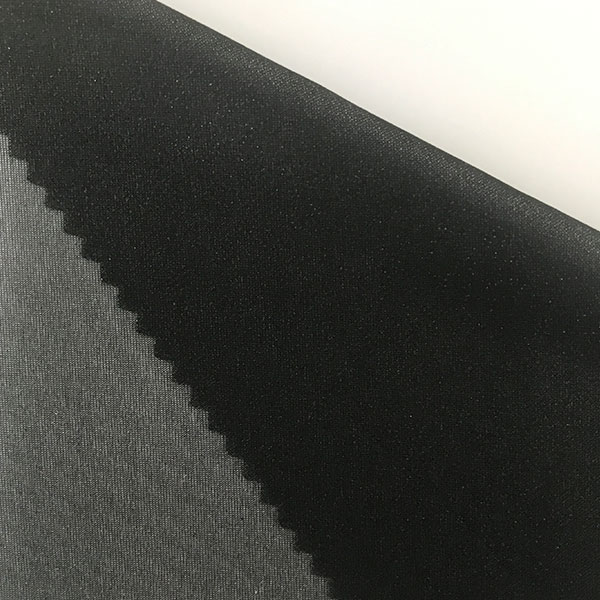

High temperature washing 9220 circular knitted fusible interlining is made of 20D super fine polyester with elastic yarn as raw material, warp and weft knitting, which is not affected by warp and weft yarn direction, the fabric is light and thin, with good elasticity and softness. Generally use PA glue powder, using double dot glue coating process, the production of interlining products after bonding does not roll the edge, not deformed, strong adhesion and impervious to glue, decoupling, high temperature washable, dry cleaning and other characteristics.

| Base fabric composition: | polyester |

| Yarn count information: | 20D*20D |

| Backing fabric process: | weft knitting |

| Backing weight: | 30g |

| Powder type: | PES, PA |

| Coating powder weight: | 8g |

| Gluing process: | double dot |

| Hand hardness: | S |

| Width range: | 122CM-190CM |

| Color: | bleached white, black, natural white |

| MOQ: |

5000m |

| Packing quantity: |

according to customer's demand |

| Packing material: |

polybag |

| Packing quantity: |

60,000/20 feet, 17-200,000/40 feet |

| Customs code: |

5903909000 |

| PES rubber powder pressing temperature |

135-140 degrees |

| PES rubber powder pressing pressure: |

2-3KG |

| PES adhesive powder pressing time: |

12-15 seconds |

| PES powder peel strength: |

10N |

| PA powder pressing temperature: |

140-145 degrees |

| PA powder pressing pressure: | 2-3KG |

| PA powder pressing time: | 12-15 seconds |

| PA powder Peel strength: | 14N |

Backing production: Polyester filament yarn - stretching - embryo fabric weaving - embryo fabric shaping, complete the production of the base fabric. Coating and gluing: Coating (you can choose PES or PA powder, using single dot or double dot coating process)--Reel formation--Inspection--Separation--Packaging

Knitted fusible interlining use: suitable for light and thin fabrics, mainly used in middle and high-grade women's clothing, fashion, high-grade children's clothing, high-grade knitwear sportswear, middle and high-grade casual shirts, etc., mainly used in the collar, front body, waist head, pocket cover, placket, and other parts.

|

|

|

| 9275 Circular Knitted Fusing Interlining | 50D28 Circular Knitted Stretch Interlining | 9350 Circular Knitted Fusible Interlining |