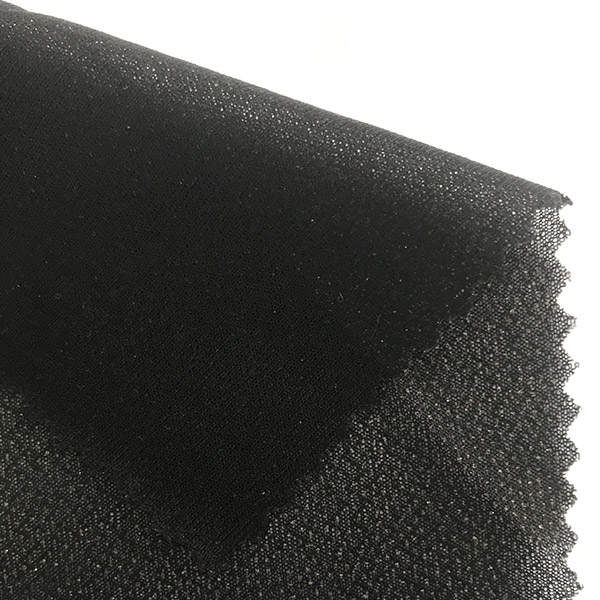

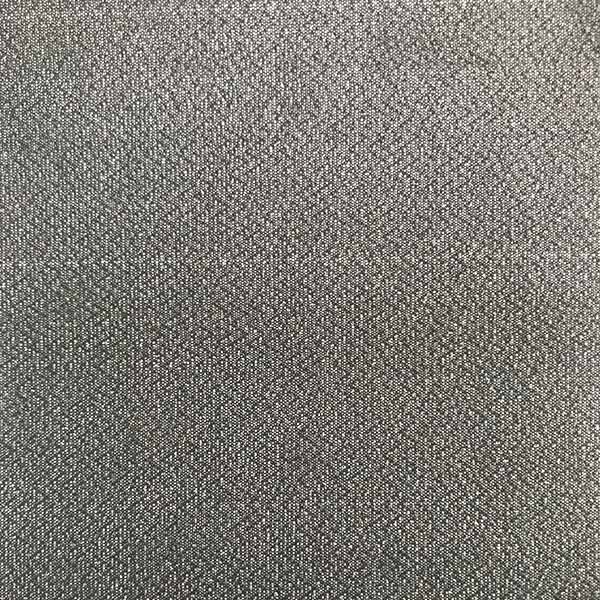

9350 Circular knitting fusible interlining is made of 50D polyester filament yarn, which is knitted by a knitting machine and is not affected by warp and weft yarn direction. It is elastic in all directions after the process of elasticization. The finished product is circular knitting fusible interlining after coating and gluing according to requirements.

| Base fabric composition: | Polyester 100% |

| Yarn count information: | 50D*50D |

| Backing fabric process: | Weft knitting |

| Backing weight: | 48g |

| Powder type: | PES, PA |

| Coating powder weight: | 10g |

| Gluing process: | Powder or double dot |

| Hand-feel: | Soft |

| Width range: | 150CM-190CM |

| Color: | Bleached white, black, natural white |

| MOQ: |

5000m |

| Packing quantity: |

According to customer's demand |

| Packing material: |

Polybag |

| Packing quantity: |

60,000/20ft, 17-200,000/40ft |

| Customs code: |

5903909000 |

| PES rubber powder pressing temperature |

135-140 degrees |

| PES rubber powder pressing pressure: |

2-3KG |

| PES adhesive powder pressing time: |

12-15 seconds |

| PES powder peel strength: |

10N |

| PA powder pressing temperature: |

140-145 degrees |

| PA powder pressing pressure: | 2-3KG |

| PA powder pressing time: | 12-15 seconds |

| PA powder Peel strength: | 14N |

Backing production: Polyester filament yarn - stretching - embryo fabric weaving - embryo fabric shaping, complete the production of the base fabric. Coating and gluing: Coating (you can choose PES or PA powder, using single dot or double dot coating process)--Reel formation--Inspection--Separation--Packaging

Circular knitted interlining is mainly used for knitted fabrics, woolen fabrics, spring, summer, and autumn men's and women's clothing, denim clothing, children's clothing, and other apparel.