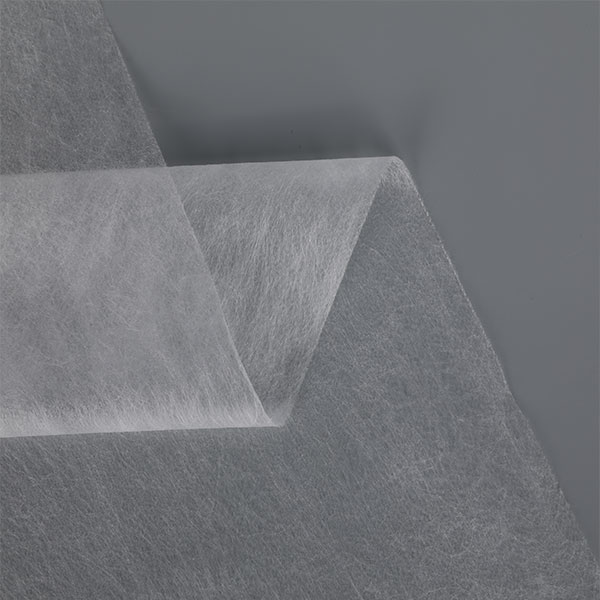

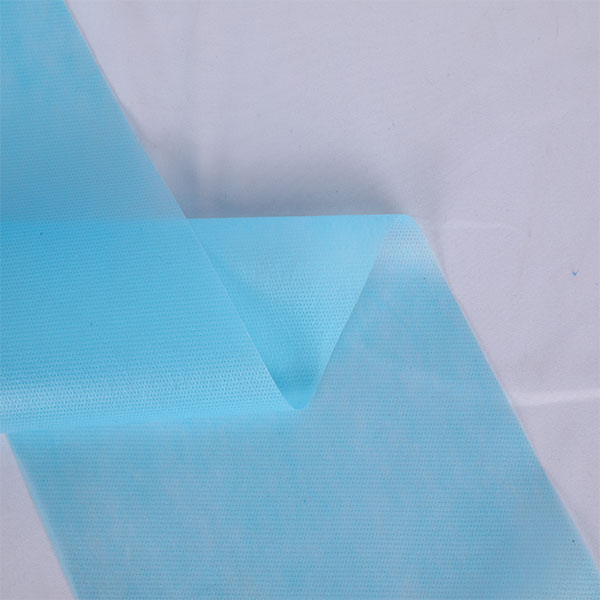

SF microporous film laminated PP nonwoven fabric is a pre-prepared PE film, heated by a hot melt glue machine to melt the friendly green hot melt glue to make it atomized on the nonwoven fabric, bonded together with the nonwoven substrate, and finally pressed together. Through the lamination process, two or three layers of fabrics can be laminated together to produce products with special functions, such as high strength, alcohol resistance, blood resistance, high barrier, high hydrostatic pressure resistance, etc. The application of SF microporous film laminated PP nonwoven fabric is very wide, in the fields of medical, health, protection, industry, and automotive industry.

Detailed Specifications: 100% virgin low-density PE material, CPE film can be made in plain, small square, sesame-shaped rolled dots, and other specific detailed specifications and parameters. The base material is 100% virgin PP material, can do rhombus, sesame-shaped rolling point, and other detailed specifications and parameters.

| Composition: | Polypropylene polyethylene |

| Grammage range: | 40-200gsm |

| Width range: | 10-200CM |

| Color: | White/blue/green or customized |

| MOQ: | 1000kgs |

| Feel hardness: | Standard |

| Packing quantity: | 1000M or according to the customer's requirement |

| Packing material: | PE transparent plastic bag |

| Loading capacity: | 12~14T/40ft high container |

| Customs Code: | HS 39209990.90 |

SF microporous film laminated PP nonwoven fabric with polyethylene film and nonwoven fabric as raw materials, glue composite machine before the upper axis of the nonwoven fabric → glue spraying machine atomized molten hot melt adhesive → glue composite machine after the upper axis of the PE film → rolled on the rubber roller to set the shape of the composite together → correction of treatment → traction → rolled material → rest for a period of time to wait for product performance stability → inverted cloth slitting → weighing and packing

|

|

|

| Bicomponent Nonwoven Fabric | PP+PE Filmed Non-woven Fabric | PE Laminated Non Woven Fabric |