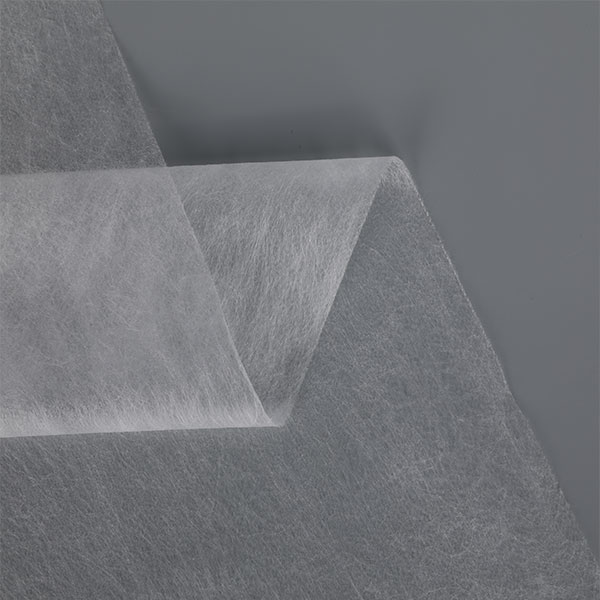

PP+PE Filmed Non-woven fabric is also called laminated nonwoven, by adding a layer of plastic film on the nonwoven, generally, the plastic is heated to a hot melt state at a high temperature and cooled on the nonwoven to form the product, which has a good isolation effect. Flame retardant laminated nonwoven is produced by adding a certain amount of flame retardant masterbatch to turn it into flame retardant laminated nonwoven.

Detailed specifications: PP+PE (ratio according to customer requirements and production)

| Composition: | Polypropylene + Polyethylene |

| Grammage range: | 25GSM -100GSM |

| Width range: | 30CM-220CM |

| Color: | White or customized |

| MOQ: | 3000KGS |

| Feel hardness: | Standard |

| Packing quantity: | According to customer's requirement |

| Packaging material: |

PE winding film |

| Loading quantity: | 40/20ft container |

It has a good isolation effect.

By adding a layer of plastic film to the non-woven fabric, the product is generally formed by coating the non-woven fabric with plastic that has been heated to a hot melt state at high temperatures and cooled.

Medical tents, isolation gowns, surgical sheets, surgical hole towels, tablecloths, etc.

|

|

|

| Bicomponent Nonwoven Fabric | SFS Laminated Non-woven Fabric | SS/SSS PP Non-woven Fabrics |