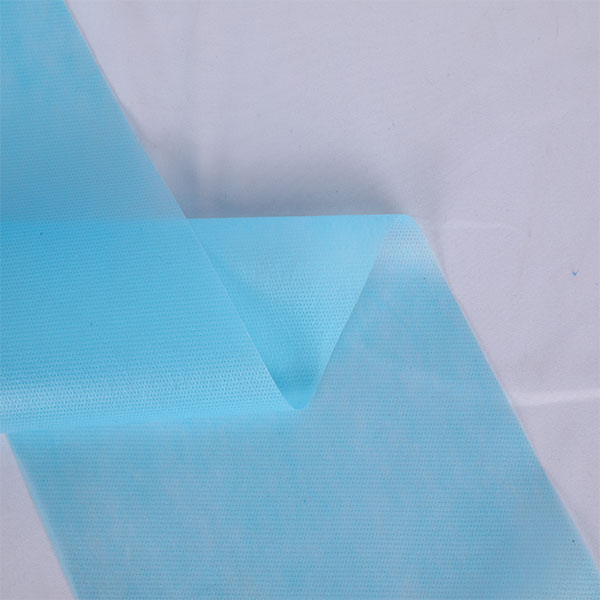

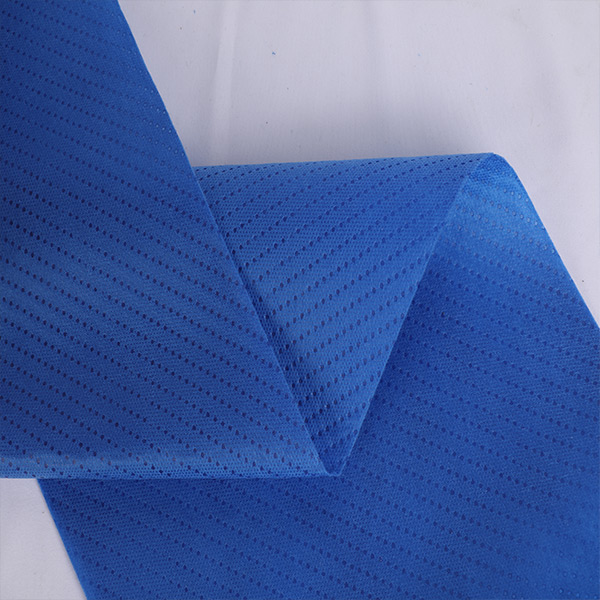

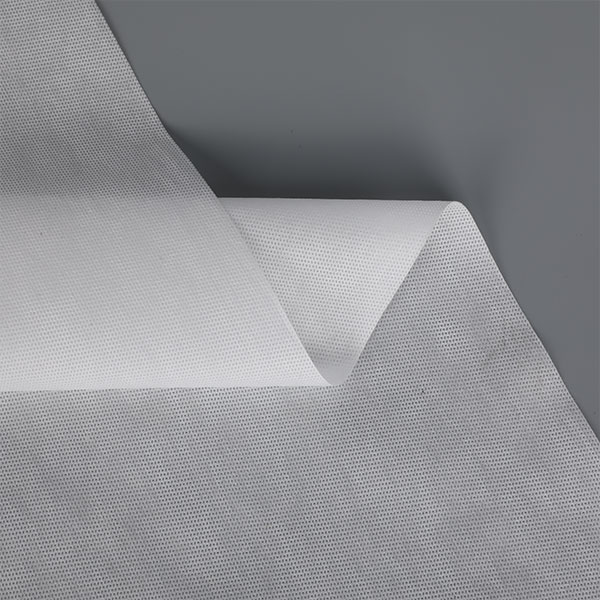

The Bicomponent nonwoven fabric is made of polypropylene and polyethylene-based particles. After melting at high temperature, the polymer is extruded and stretched to form continuous filaments, and then the filaments are laid into a web through airflow traction, and the fiber web is then processed into a nonwoven fabric through a thermal bonding reinforcement method. The composite spunbond nonwoven fabric skin layer is made of low-melt PE material, and the core layer is made of PP material.

Detailed specifications: 50% PP + 50% PE material, can do sesame-shaped rolling point, etc. Specific detailed specifications and parameters.

| Composition: | Polypropylene + Polyethylene |

| Grammage range: | 10GSM -100GSM |

| Width range: | 10CM-320CM |

| Color: | White or customized |

| Order quantity: | 1000KGS-3000KGS |

| Feeling hardness: | Super soft |

| Packing quantity: | According to customer requirements |

| Packing material: | PE winding film |

| Loading quantity: | 40/20ft container |

The breakthrough use of two-component spunlace reinforcement provides better thermal bonding strength than traditional single-component spunbond fabric. The hydrophilic treatment process has good hydrophilicity and permeability, as smooth and comfortable as silk.

A good application in diaper waistband, baby diaper bottom film, food packaging, etc.

|

|

|

| PP+PE Filmed Non-woven Fabric | SFS Laminated Non-woven Fabric | SS/SSS PP Non-woven Fabrics |