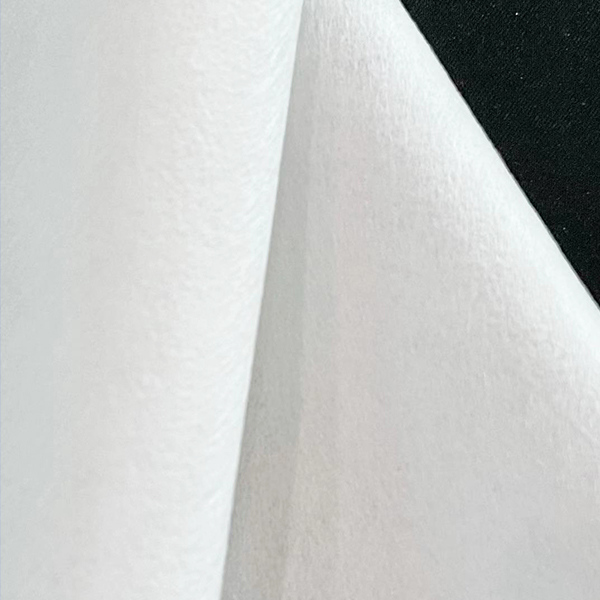

Product Definition:

Cotton spunlace nonwoven fabric is made of natural fiber cotton, after opening and loosening the cotton, using a cutting-edge carding machine and net spreading machine and drafting machine to finish the cotton into a net, pressurized to form a high-density needle-like water column, and then using a hydroentanglement machine to facilitate the entanglement of cotton fibers into fabric. It takes only 5 minutes from the raw cotton to the fabric, which saves the spinning and weaving link, shortens the working hours, and saves a lot of energy, labor, and equipment than the traditional weaving fabric. Its process has the world's advanced level of cloth-forming technology, low-carbon environmental protection, energy saving and emission reduction, reducing costs by about 30%.

Detailed Product Specifications and Parameters:

| Ingredients: |

100%cotton |

| Grammage range: |

30-150gsm |

| Width range: |

6-220cm |

| Color: |

white, customized |

| MOQ: |

1000kgs |

| Handfeeling: |

soft, medium |

| Packing quantity: |

100M/roll |

| Packing material: |

Polybag |

Product Features and Advantages:

- Cotton spunlace nonwoven fabric has flexible tangles that do not affect the original characteristics of the fiber. Its appearance is closer to traditional textiles than other non-woven materials.

- High strength, low linting, fast moisture absorption, good breathability, soft feel, fluffy, high moisture absorption, certain oil absorption effect;

- No adhesive reinforcement, natural and environmental protection, washable;

- According to the need can do with flame retardant, antibacterial, water repellent, anti-static, and other additional treatments.

The Cotton Spunlace Nonwoven Fabric Process:

The production process can be divided according to the different ways of lapping.

Option A, straight lapping, which has good longitudinal tension and poor transverse tension, lower cost, and is suitable for leather-based fabrics. Process: Fiber raw material - open blending - carding - lapping - drafting - pre-wetting - double-sided spun - finishing - drying - winding - water treatment cycle.

Option B, cross lapping, which has a stronger cross and longitudinal strength, less tearing, higher cost, and is suitable for spunlace. Process: Fiber raw material - open and mixed - carding mess into a network - pre-wetting - double-sided spunlace - post-finishing - drying - winding - water treatment cycle.

Product Applications:

- Cotton spunlace nonwoven fabric is used in a wide range of applications due to its excellent performance, mainly including:

- Medical hygiene products: disposable surgical dressings, sterile wipes, wound dressings, surgical cavity wipes, etc.

- Dry and wet wipes, including disposable wet products, catering wipes, and wet products for make-up.

- Household hygiene products, including cosmetic pads, face masks, sanitary napkins, pads, baby and adult diapers, etc.

- Personal care products such as cotton face towels, napkins, soft towel rolls, cotton soft towels, etc.

You May Also LIke: