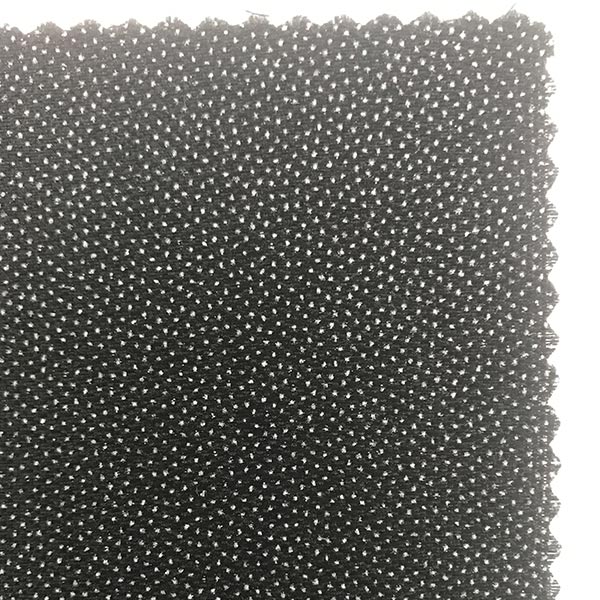

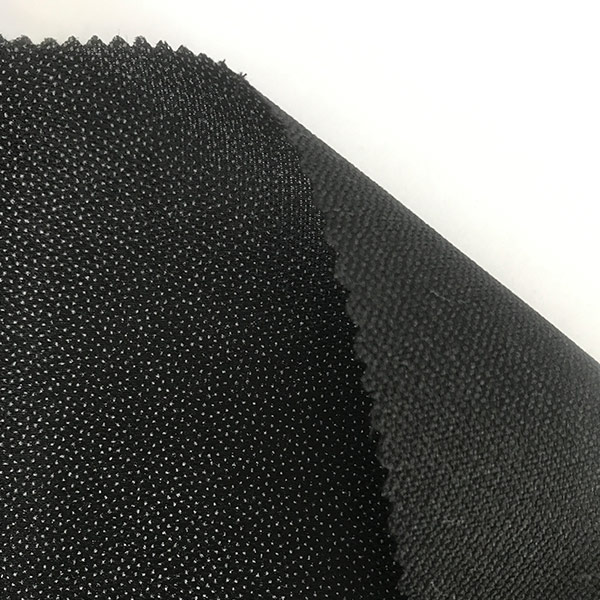

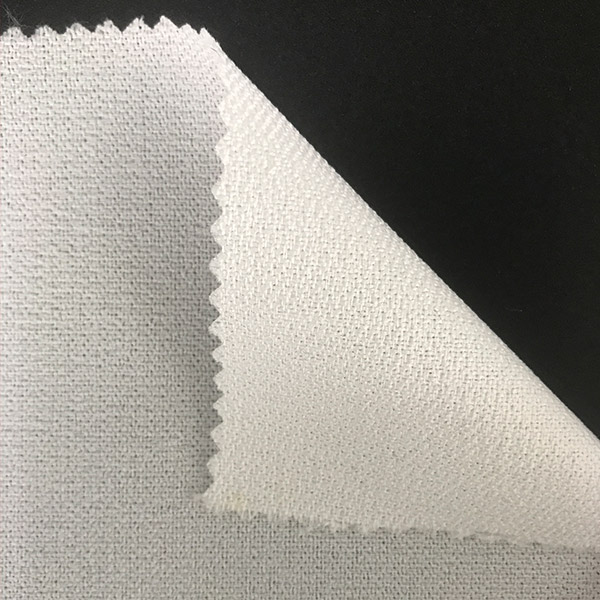

69200 woven fashion fusing interlining differs from 69100 in that resin is added to the base fabric to stiffen the feel and meet the customer's specific needs for thickening, stiffening, and stiffening of garments or other textiles. The material is also made of 75*300D all polyester yarn, woven twill base fabric produced by water jet loom and processed by double dot technology using environmentally friendly PA hot-melt the adhesive powder.

| Base fabric composition: | 100% polyester |

| Yarn count information: | 75D*300D |

| Backing fabric process: | Twill |

| Weight: | 110GSM |

| Glue powder type: | PA |

| Gluing process: | Double dot |

| Hand hardness: | Medium/hard |

| Width range: | 112CM/150CM |

| Color: | BLK/WHT |

| Order quantity: | 3000M |

| Customs code: |

590390 |

| PA powder pressing temperature: |

130-145DEGREE |

| PA powder pressing pressure: |

2.5KGS |

| PA powder pressing time: | 12-15SEC |

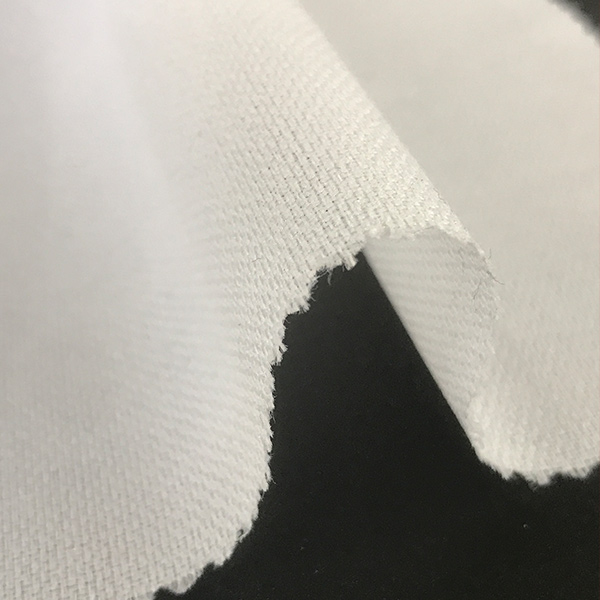

Woven fashion fusing interlining is made of 75D*300D polyester yarn as raw material, using a water jet loom to produce twill base fabric, adding resin raw material at the time of basic shaping to obtain stiffened hand feeling base fabric, then coating a layer of PA glue powder adhesive on the surface, it forms a spun fashion interlining, the specific raw process is. Embryo production - dyeing - shaping (add resin to adjust the feel) - gluing, coating - slitting - packaging.

The woven fashion fusing interlining is thick, soft to the touch, has good elasticity, suitable for all kinds of medium thickness and a certain degree of elasticity of the fabric, such as all kinds of professional clothing, autumn and winter clothing, men's clothing, jackets, coats, etc...

|

|

|

| 69100 Twill Woven Fashion Fusing Interlining | 64120 Twill Woven Fashion Fusing Interlining | 66715 Twill Water Jet Loom Woven Interlining |