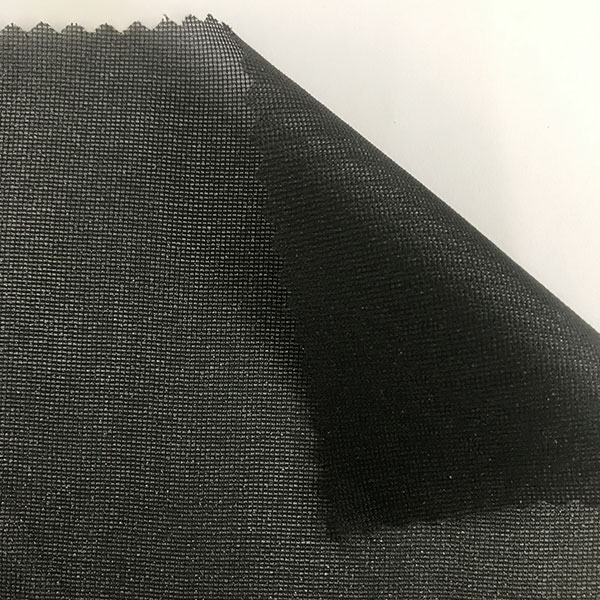

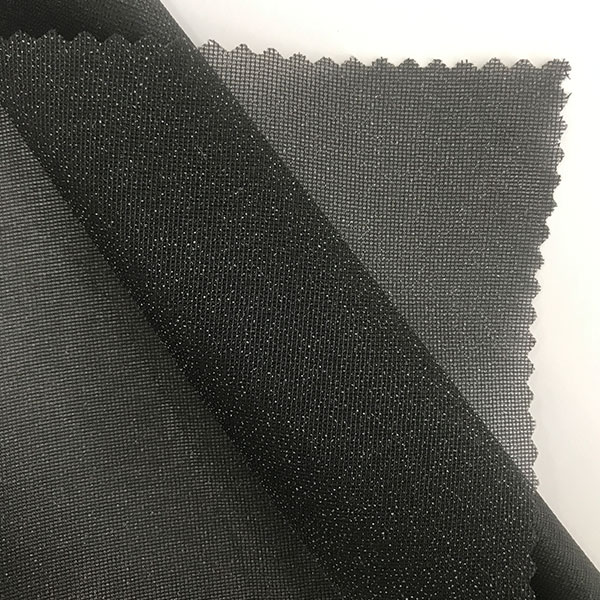

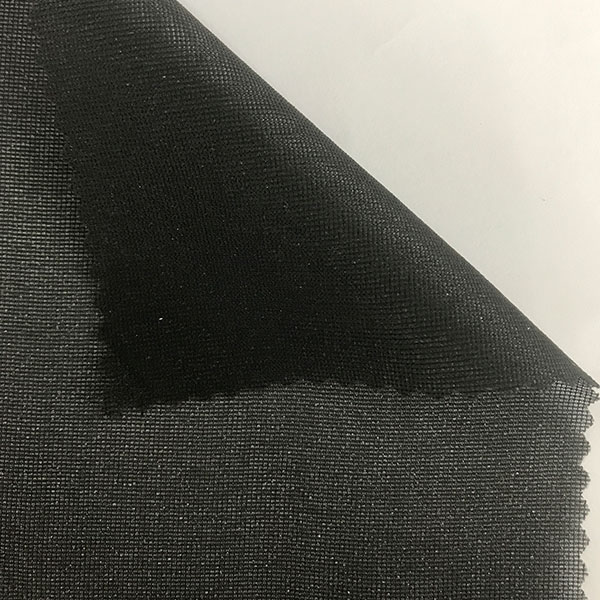

Tricot fusible interlining is made of polyester filament as raw material, producing woven warp knitted fabric as the backing, then choose PA or PES glue powder according to the customer's demand, choose the powder point and double point glue process, the production is woven warp knitted interlining.

| Base fabric composition: | polyester 100% |

| Yarn count information: | 40D*75D |

| Backing fabric process: | warp knitting |

| Grammage: | 44G |

| Powder type: | PES/PA |

| Gum powder weight: | 10-12G |

| Gluing process: | double dot/powder dot |

| Feeling hardness: | conventional |

| Width range: | 122/150cm |

| Color: | white/black |

| Order quantity: |

3000m |

| Packing quantity: |

50-100m/roll |

| Packing material: |

POLY BAG |

| Loading quantity: |

60,000/20 feet, 17-200,000/40 feet |

| PES rubber powder pressing temperature: |

135-140 degrees |

| PES rubber powder pressing pressure: |

2-3KG |

| PES rubber powder pressing time: |

12-15 seconds |

| Peel strength: |

10N |

| PA powder pressing temperature: |

140-145 degrees |

| PA powder pressing pressure: |

2-3KG |

| PA adhesive powder pressing time: |

12-15second |

| Peel strength: |

14N |

Generally use polyester filament as raw material, the production process includes base fabric weaving - shaping - coating and gluing - rewinding - the packaging

9612 Woven tricot interlining product features thin and light, ideal for all kinds of light fabrics, but also suitable for all kinds of men and women formal wear, coats, suits, etc.