Using chemical fiber as raw material, after opening, carding, and forming a net, it is chemically bonded and dried at high temperature into cloth.

Detailed specifications: 100% polyester chemical fiber

| Composition: | 100% polyester |

| Gram weight range: | 20GSM-100GSM |

| Width range: | Match within 2 meters |

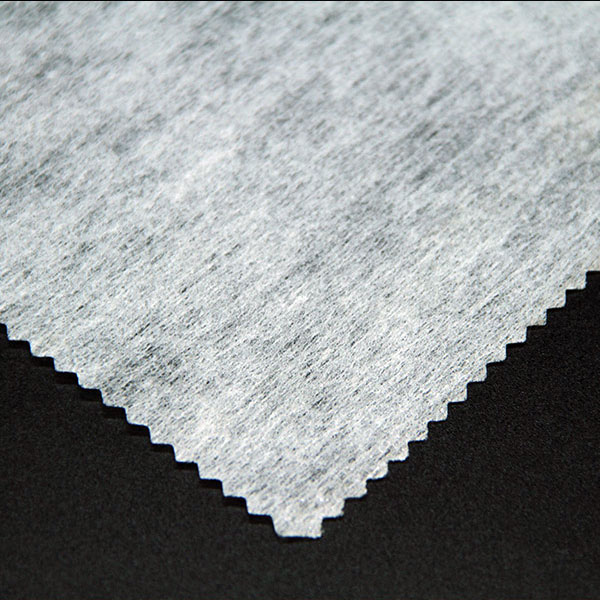

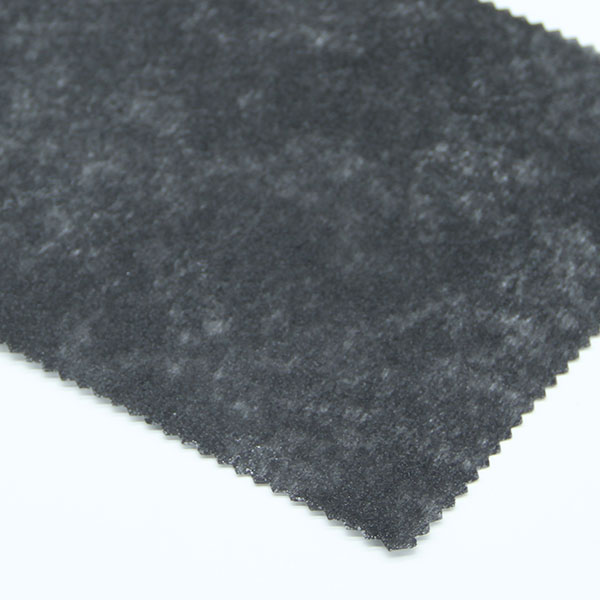

| Colors: | White, Black |

| MOQ: | 5000 meters |

| The hand feel hardness: | Hard, soft hand feel |

| Packing quantity: | According to customer requirements |

| Packaging material: | Film bag |

| Loading capacity: | 20GT/40HQ |

The production process of nonwoven fabric generally includes the following parts: web formation, reinforcement, and roll cutting. Impregnated nonwoven fabric is made by passing the formed cotton web through the impregnation tank, then drying it into cloth, and finally, roll cutting.

You May Also Like:

|

|

|

| Soft LDPE Glue Foam Bonding Non Woven Interlining Fusing | 55Gsm Foaming Impregnated Non-Woven Fabric | Soft LDPE Impregnated Non Woven Interlining Fusing Paper |