What Is Warp Knitted Fabric?

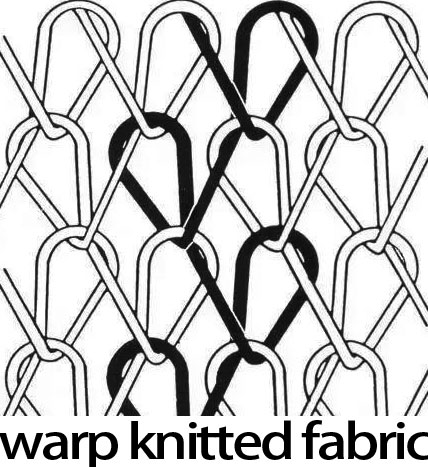

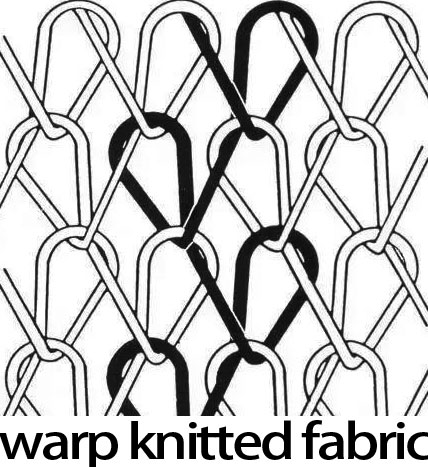

Warp knitted fabric is knitted or woven by a warp-knitting textile process. From the weaving machine warp feed one or several parallel strands of yarn, knitted is called warp knitted fabric. Those in the form of looped yarns are called warp-knitted knitted fabrics.

Warp knitted fabric is knitted or woven by a warp-knitting textile process. From the weaving machine warp feed one or several parallel strands of yarn, knitted is called warp knitted fabric. Those in the form of looped yarns are called warp-knitted knitted fabrics.

How About the Warp Knitted Fabric Properties

Warp knitting is the simultaneous matting of all knitting needles into loops. The structure, properties and advantages of warp knitted fabrics are as follows.1. Warp knitted knitted fabric production efficiency is high, the highest machine speed has reached 3600rpm, door width of 210 inches, and efficiency of up to 98%.2. Warp knitted knitted fabrics generally have less elongation and very good dimensional stability.3. Warp knitted knitted fabric has good anti-dispersion. It can use different tissues and reduce the kind of weft knitted knitted fabric due to broken yarn, holes, and coil dispersion caused by now.4. Warp knitted knitted fabric can use different thicknesses of yarn, and different lining weft knitting, and thus can form different forms of mesh organization, pattern change is simple, so almost all the fabric organization can be knitted out.5. In the production of mesh fabrics, compared with other production technologies, warp knitting technology has more practicality. The mesh fabric produced can be of different sizes and shapes, and the fabric shape is stable and does not need to undergo any special finishing to make the fabric strong.6. Warp knitting can produce formed products such as pantyhose, pants, seamless tights, and gloves using a double needle bed.

Warp Knitted Fabric Uses:

The main applications of warp-knitted fabrics can be classified according to their usage.

1. Knitted fabrics for garments: such as underwear, outerwear, sportswear, swimwear, headscarves, socks, gloves, etc.

2. Decorative knitted fabrics: such as window screens, curtains, drapes, tassels, bedspreads, sofa sheets, tablecloths, carpets, car cloths, wall coverings and other furniture decorative fabrics, pillowcases, bed sheets, mosquito nets, bath towels, towels, etc.

3. Industrial warp knitted fabrics: such as sieve, fishing net, conveyor belt, water hose, insulation cloth, filter cloth, oil tank cloth, parachute, seedling net, forestry net, tent, geotechnical cloth, gauze, bandage, hemostatic cloth, artificial blood vessel, etc.

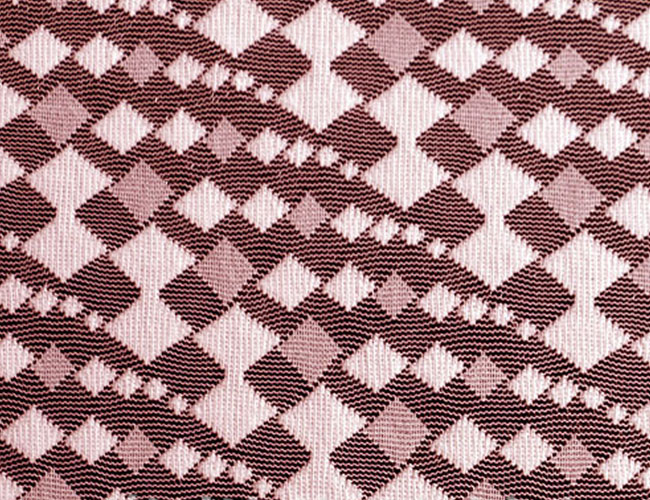

Warp Knitted Fabric Types:

1. Warp knitted polyester fabric: flat surface, bright color, thick and thin type. Thin type is mainly used as a shirt, and skirt fabric; medium-thick, thick type can be used for men and women in coat, windbreakers, tops, suits, pants, and other fabrics.

2. Warp knitting pile fabric: mainly used as winter men's and women's coats, trench coats, tops, pants, and other fabrics, fabric drapability, easy to wash, quick dry, non-iron, but in use static electricity accumulation, easy to absorb dust.

3. Warp knitted mesh fabric: taking mesh fabric texture is thin, elastic and breathable, feel smooth, and soft, mainly used as summer men's and women's shirt fabric.

4. Warp knitting velvet fabric: surface pile dense towering, feel thick, full, soft, elastic, good warmth, mainly used as winter clothing, children's clothing fabric, warp knitting terry fabric: this fabric has a rich and thick feel, cloth body firm and thick, elastic, moisture absorption, good warmth, terry structure stable 5 fixed, with good performance, mainly for sportswear, lapel T-shirt, pajama pants, children's clothing, etc.

What Is The Difference Between Warp Knitted Fabrics and Weft Knitted Fabrics?

1. Warp knitting uses many yarns to form loops in sequence along the longitudinal (warp) side of the fabric at the same time.

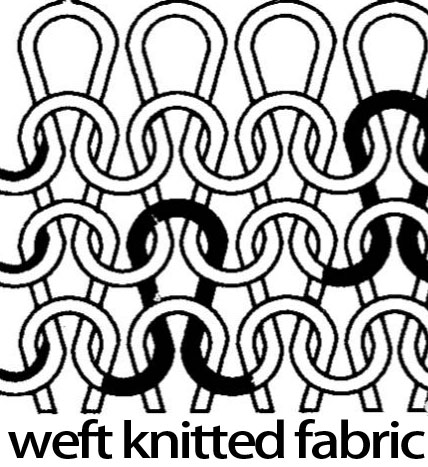

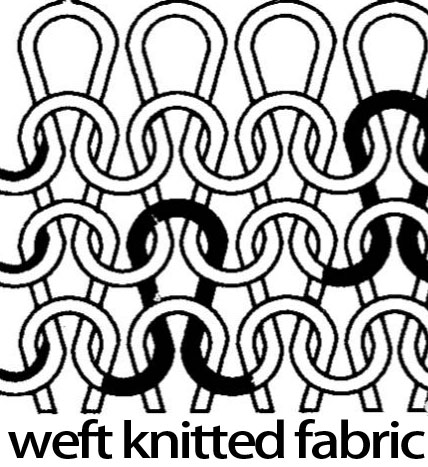

2. Weft knitting uses one or more yarns to form loops in sequence along the transverse (weft) side of the fabric.

3. Weft knitted fabrics can be formed with at least one yarn, but to increase production efficiency, many yarns are generally used for knitting;

4. Warp knitted fabric with yarn is not able to form the fabric, a yarn can only form a coil of the composition of the-like material.

5. Warp knitted knitted fabrics and weft knitted fabrics, compared with the general extension is relatively small. Most of the weft knitted fabric transversal has a significant elongation.

6. And warp knitted knitted fabric elongation with the number of comb tape and organization, some warp knitted fabric transverse and longitudinal have elongation, but some fabrics are very good dimensional stability.

7. All the weft knitted fabrics can opposite the direction of knitting off into line, but warp knitted fabrics can not.

8. Warp knitted fabrics cannot be hand knitted.

Conclusion.

That's all about warp knitting fabric, if you want to know more about other fabrics, welcome to our website www.groupgf.com. G&F GROUP INC. is a professional fabric wholesaler with complete fabrics, fast delivery, and 20 years of wholesale experience, you can be completely assured. Come to the message and tell us your needs, we look forward to hearing from you.

Nonwovens in daily life ----- filtration

Nonwovens in daily life ----- filtration

Nonwovens in daily life ----- automotive

Nonwovens in daily life ----- automotive

What is SAP – superabsorbent polymers

What is SAP – superabsorbent polymers

The Future of Global Nonwoven Wipes to 2029

The Future of Global Nonwoven Wipes to 2029