Today PTFE has been used in many fields of production and life, but also partly in military technology and weapons.(Source: https://en.wikipedia.org/wiki/Polytetrafluoroethylene#History)

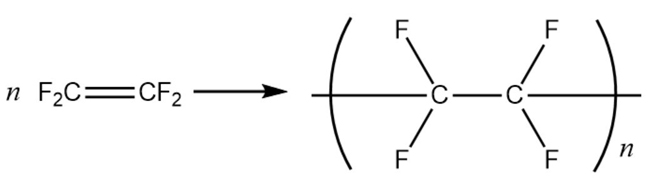

What Is PTFE Made Of?

The manufacturing method of polytetrafluoroethylene fibers. Industrial production by suspension polymerization method or emulsion polymerization method. It includes mixing, sieving, performing, extrusion, calendering, de-lubrication, stretching and shaping, and slitting. In the following steps.

Mixing: Low surface tension lubricating oil is mixed into the PTFE micronized powder in an amount of 10% of the mass of the PTFE micronized powder. The particle size of the chosen PTFE micro powder is 0.215 to 0.225 microns.

Sieving: Sieving of the above mixes with a 10-mesh sieve.

Preforming: Place the sieved mixes at a temperature of 20 °C for 20 hours.

Extrusion: The above-preformed material is extruded using an extruder. The extrusion parameters are as follows. Extrusion speed of 5 mm/min, extrusion diameter of 15 mm, mouth film L/D ratio of 20, cone angle of 30°, and a compression ratio of 140.

Calendering: use the calendar to calendering the extruded raw material. The temperature of the rollers is controlled to 140℃ during calendering; raw material tape is produced.

De-lubrication: drying the said raw material strip at a temperature above the boiling point of said low surface tension lubricant for 18 hours. Removal of said low surface tension lubricant.

Stretching and sizing: The raw material strip is stretched while the low surface tension lubricant is removed. Then a primary heat setting is performed; followed by a first transverse stretching, a second heat setting, a second transverse stretching, and a third heat setting to produce a microporous filter membrane. The control parameters during stretching and sizing are shown in the following table.

| Table of Process Parameters for Stretching and Shaping Steps |

|

Longitudinal stretching rate

|

1%/sec |

| Longitudinal stretching multiplier |

2 |

| First heat setting temperature |

200℃ |

| First transverse stretching rate |

10mm/sec |

| First transverse stretching times |

2 |

| Secondary heat setting temperature |

200℃ |

| Re-transverse stretching rate |

40mm/sec |

| Again transverse stretching times |

50 |

| Third-time heat setting temperature |

250℃ |

Slitting: The microporous filter membrane is slit into PTFE fiber by a slitting machine.

The 8 Advantages Of PTFE.

High Temperature Resistance

It can be used at a temperature of 250°C. Generally, when the temperature of plastic reaches 100°C, the plastic will dissolve on its own. But when Teflon reaches 250°C, it can still keep the structure unchanged. And even when the temperature reaches 300°C, there will be no change in physical form.

Low Temperature Resistance

At low temperatures down to -190°C, it can still maintain 5% elongation.

Corrosion Resistance

Most chemicals and solvents show inertness and can resist strong acids and bases, water and various organic solvents.

Weather Resistant

Teflon does not absorb moisture, and is not easy flammable. It is stable to oxygen and ultraviolet light, so it has the best aging life among plastics.

High Lubrication

Polytetrafluoroethylene is so smooth and unusual that even ice can't compete with it. So it is one of the solid materials with a low coefficient of friction.

Non-adhesive

It does not adhere to any substance because of the low intermolecular forces between oxygen-carbon chains.

What Is PTFE Used For?

The common function of PTFE makes it widely used in chemical, petroleum, textile, food, paper, medical, electronic, and mechanical industries, and marine operations.

Application of Anti-corrosion

PTFE material has become the primary corrosion-resistant material for petroleum, chemical, textile, and other industries with its outstanding corrosion-resistant function. Its detailed use contains transport corrosive gas delivery pipe, exhaust pipe, steam pipe, rolling mill high-pressure oil pipe, plane hydraulic system and cold pressure system of high school and low-pressure pipe, distillation tower, heat exchanger, tower, tank lining, broad door, and other chemical equipment.

The coefficient of friction and the characteristics of non-stick, wide temperature resistance scale, and good elasticity make it very suitable for use in making seals with high corrosion resistance requirements and using temperatures higher than 100°C. Such as machines, heat exchangers, high-pressure vessels, large diameter vessels, valves, seals for grooved flanges of pumps, seals for glass reaction pots, flat flanges, large diameter flanges, and seals for shafts, piston rods, valve rods, waist pumps, tie rods, etc.

Applications in Machinery

This makes filled PTFE the ideal material for oil-free lubrication (direct load acceptance) of mechanical equipment parts. This is because the material has the lower conflict coefficient of any known solid material. Its detailed uses include bearings for chemical equipment, paper machinery, agricultural machinery, piston bad, machine tool guide, and guide ring.

It is used in civil engineering and construction as the supporting slider of bridges, tunnels, steel roof frames, large chemical pipelines, and storage tanks, as well as for bridge bearings and bridge rotors, etc.

Applications in Electronics and Appliances

PTFE's inherent low loss and small dielectric constant allow it to be used as enameled wire for micro motors, thermocouples, control devices, etc. PTFE film is an ideal insulating material for capacitors, radio insulation gaskets, insulated cables, motors, and transformers, and is one of the indispensable materials for electronic components in aerospace and other industries. The selective permeability of fluoroplastic film. It has a high permeability to oxygen and a low permeability to water vapor and can be used to make oxygen sensors.

Because of their ability to deflect charges at high temperatures and pressures. Fluoroplastics can be used for microphones, speakers, robot parts, etc. The low refractive index makes it possible to make optical fibers.

Applications in Medical and Pharmaceutical Fields

Due to the excellent biocompatibility of PTFE. Many people have conducted in-depth research on it as biological material. In recent years, PTFE membranes have been developed at home and abroad for use as artificial organs. Such as artificial blood vessels, heart valves, etc. For example, it has been used as artificial blood vessels and prosthetic stent materials in rhinoplasty. These have achieved good results.

Application of Anti-adhesive Function

PTFE material has a small to medium surface tension to solid material and does not adhere to any substance. And it has the characteristics of high and low-temperature resistance, which makes it very used. For example, the production of non-stick pan anti-adhesive. The anti-stick process consists of two main types: Mounting PTFE parts or sheets on the substrate and mounting PTFE coating or coating with glass. PTFE coating or glass laminate is applied to the substrate by heat shrinkage

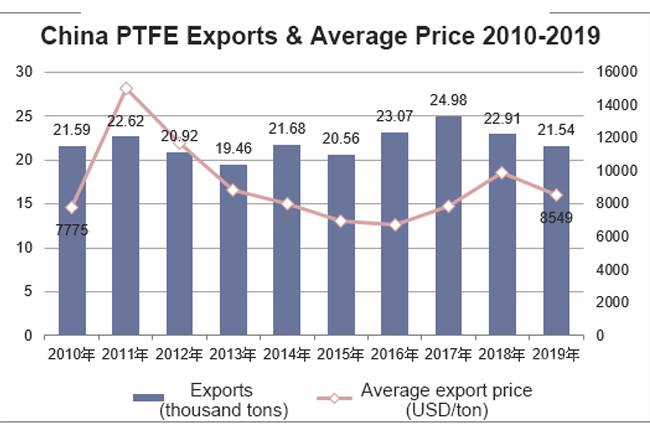

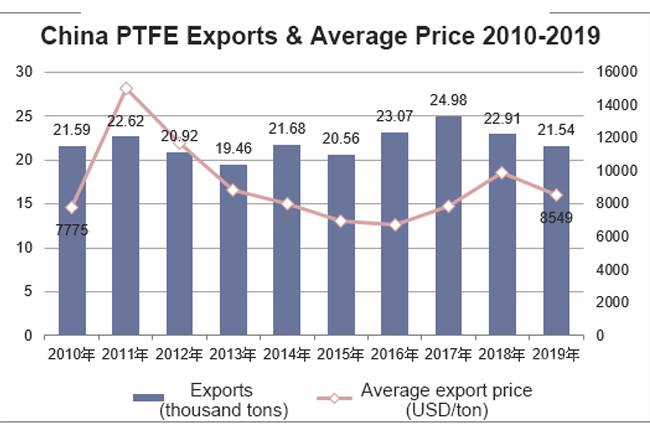

Where Is PTFE Fabric Produced?

China has become a major producer and supplier of PTFE worldwide. 2021 average price of imported primary-shaped PTFE in China is 45% higher than the average price of exported primary-shaped PTFE. Both global and Chinese PTFE usage is increasing year by year. With the rapid expansion of China's PTFE production capacity and enterprise technology upgrades. China's low and mid-range PTFE products achieve import substitution, but high-end products are still dependent on imports. Paying attention to R&D investment and new product development will bring a larger profit margin to enterprises.

If you have a demand, you can contact us at G&F.

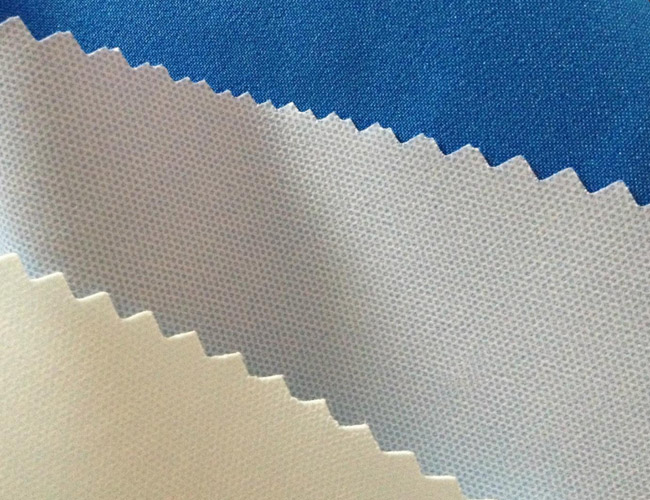

3 Types of PTFE Fabric.

According to the preparation method. There are three main categories of PTFE: suspension method resin, dispersion resin and concentrated dispersion.

Suspension method PTFE

Used in the manufacture of mechanical industry seals, gaskets, etc., and chemical equipment with pumps, valves, pipe fittings, equipment lining, etc... Besides in the manufacture of electrical insulation parts, film, etc.

Dispersion Method PTFE

Dispersion PTFE is used for manufacturing corrosion resistant, high temperature resistant, high dielectric wire and cable. In the chemical industry. It is used to manufacture filament sealing raw material belts, pipelining, etc.

PTFE Concentrated Dispersion

PTFE concentrated dispersion is used as an anti-adhesive coating in food, textile, printing and dyeing, paper making, and other industries as well as impregnating glass cloth and asbestos. It can also be used for glass fiber and porous materials.

How Much Does PTFE Fabric Cost?

Polytetrafluoroethylene is an ideal material for corrosion protection. Its price varies according to market conditions and different applications.

It needs to be checked in real-time according to the situation Polytetrafluoroethylene (PTFE for short) has a high degree of chemical stability, it can resist almost all common strong corrosion, and hydroxide chemicals, but also has the characteristics of high-temperature resistance, so it is an ideal anti-corrosion material.

With the progress of science and technology, the development of traditional corrosion-resistant non-metallic material system corrosion prevention equipment is becoming more and more perfect, and new corrosion-resistant non-metallic material products are emerging. Want to know the specific price, welcome to contact us.

Is Polytetrafluoroethylene Fabric Harmful?

In general, Teflon is toxic, and the Teflon coating has some toxic side effects. So, in the case of high heat burn or in the case of full combustion, PTFE coating will appear as PTFE leakage and leakage. In this case, direct contact with human skin and eyes must be avoided, as there is a risk of serious damage to the eyes. In the incineration process, it will also cause an environmental impact, and the substance is not biodegradable.

Conclusions.

This is the end of the introduction of polytetrafluoroethylene(PTFE) fabric. G&F is a leading manufacturer and supplier of garment fabrics in China, with 20 years of experience in direct sales.

All Rights Reserved: https://www.groupgf.com/info-detail/ptfe-polytetrafluoroethylene-fabric

Copyright Notice: This is an original (translated) article from G&F Group Inc., please indicate the source from G&F Group Inc.. If there is any infringement, please contact us first.

Nonwovens in daily life ----- filtration

Nonwovens in daily life ----- filtration

Nonwovens in daily life ----- automotive

Nonwovens in daily life ----- automotive

What is SAP – superabsorbent polymers

What is SAP – superabsorbent polymers

The Future of Global Nonwoven Wipes to 2029

The Future of Global Nonwoven Wipes to 2029