Felt fabric is made of cow hair, camel hair, wool, or other animal hair. Then it is rolled into a square or rectangular sheet material by artificially popping wool, humidifying and kneading, etc... It is suitable for various padding materials and has good heat and cold resistance. It belongs to the category of non-woven fabric, with high density and high thickness, generally 2-5mm thickness can be called felt fabric. Bright and colorful, with decorative solid and practical properties.

Click here to see more pictures, specifications, colors, and quantities. Feel free to leave a message.

Felt from wool is one of the oldest known textiles. Many cultures have legends as to the origins of felt making. Sumerian legend claims that the secret of feltmaking was discovered by Urnamman of Lagash. The story of Saint Clement and Saint Christopher relates that the men packed their sandals with wool to prevent blisters while fleeing from persecution. At the end of their journey, the movement and sweat had turned the wool into felt socks.

Most likely felt's origins can be found in central Asia, where there is evidence of feltmaking in Siberia (Altai mountains) in Northern Mongolia and more recently evidence dating back to the first century AD in Mongolia. Siberian tombs (7th to 2nd century BC) show the broad uses of felt in that culture, including clothing, jewelry, wall hangings, and elaborate horse blankets. Employing careful color use, stitching, and other techniques, these feltmakers were able to use felt as an illustrative and decorative medium on which they could depict abstract designs and realistic scenes with great skill. Over time these makers became known for the beautiful abstract patterns they used that were derived from plant, animal, and other symbolic designs.

From Siberia and Mongolia, feltmaking spread across the areas held by the Turkic-Mongolian tribes. Sheep and camel herds were central to the wealth and lifestyle of these tribes, both of which were critical to producing the fibers needed for felting. As nomads traveling frequently and living on fairly treeless plains, felt provided housing (yurts, tents, etc.), insulation, floor coverings, and inside walling, as well as many household necessities from bedding and coverings to clothing. In nomadic peoples, an area where feltmaking was particularly visible was in trappings for their animals and for travel. Felt was often featured in the blankets that went under saddles.

Dyes provided rich coloring, and colored slices of pre-felts (semi-felted sheets that could be cut in decorative ways), along with dyed yarns and threads were combined to create beautiful designs on the wool backgrounds. Felt was even used to create totems and amulets with protective functions. In traditional societies, the patterns embedded in the felt were also imbued with significant religious and symbolic meaning.

Feltmaking is still practised by nomadic peoples (such as Mongols and Turkic people) in Central Asia, where rugs, tents and clothing are regularly made. Some of these are traditional items, such as the classic yurt (Gers), while others are designed for the tourist market, such as decorated slippers. In the Western world, felt is widely used as a medium for expression in both textile art and contemporary art and design, where it has significance as an ecologically responsible textile and building material.

In addition to Central Asian traditions of felting, Scandinavian countries have also supported feltmaking, particularly for clothing.

Source: https://en.wikipedia.org/wiki/Felt#History

Felt fabric making process:

Wool - screening (pick out the skin head in the wool) - open wool (open the purchased wool) - purification (extract impurities) - carbonization - drying or drying - combing (by carding machine processing) - laying net (lay the wool into a net) - rolling blank (by flat machine kneading blank) - pounding felt (making felt blank hardness) - shrinkage (felt density processing) - squeeze felt ( Felt flattening by felting machine) - Pounding felt (secondary processing felt density and cross force) - Bleaching (adjusting felt color to customer requirements generally about 6 hours) - Drying - Quality inspection - Drying - High temperature shaping - Anti-moth treatment - Felt block products or felt pads - felt strips and other felt products - Quality inspection - Storage - Factory. As the picture.

Click here to view felt cloth specifications and pictures. There are other fabrics for you to recommend below this link. Feel free to contact us.

Wash with cold water.

Felt products should not be bleached.

Choose a neutral detergent with a pure wool symbol and no bleach.

Hand wash alone, do not use a washing machine as it may damage the appearance.

Wash by hand with light pressure and scrub gently on dirty parts.

Use shampoo and rinse essence to reduce the phenomenon of pilling.

After cleaning, hang it in a ventilated place to dry naturally. If you need to dry, please use low-temperature drying.

Civil Products

Felt wool insoles-keep warm from cold

Puppet toys-safer than toys made of plastic or metal

Perfect material for various decorative and design purposes-unique quality, brilliant colors, and elegant appearance.

Home appliance industry

Recorder and camera series-anti-vibration (dust), insulation, and cleaning

Computers and cameras - Anti-vibration (dust), insulation, electromagnetic wave prevention, anti-static

Fax, telephone - anti-vibration, electromagnetic wave prevention, heat break

Microwave oven, dryer - electromagnetic wave prevention, insulation

Air conditioning - sound insulation, vibration prevention, dew condensation prevention, filtration, dust prevention

General industrial machinery

Various industrial machinery-vibration-proof, dust-proof, wear-resistant

Various motor series - vibration prevention, oil lubrication, friction resistance

Very fine wire processing - copper wire insulation coating

Dust and gas mask-filtering, dustproof

Refrigeration and freezing machines - heat insulation, thermal insulation, dew condensation prevention

Semiconductor, glass, metal-grinding

Automotive industry

Engine section - heat insulation, soundproofing, heat resistance

Oil filtration equipment for each department - filtration, oil content

Other machine transportation - heat resistance, dustproof, filtration, oil content

Sports equipment & medical equipment & musical instruments

Pianos, percussion instruments-percussion, dustproof, other gaskets

Electronic musical instruments - Anti-vibration, dustproof, insulation, other gaskets

Sports equipment - sports injury prevention pads, other

Medical equipment - pads for rehabilitation equipment, others

Printing table - Oil storage, oil storage

Billiard table - fine processing of felt can be very smooth, giving a sense of luxury

Black/white board eraser-soft, does not scratch the black/whiteboard, wear-resistant, wipe clean

1. Elastic, can be used as anti-shock, sealing, padding and elastic steel wire needle cloth backing felt material.

2. Good adhesive performance, not easy to loose, can be punched and cut into various shapes of parts.

3. Good heat preservation performance, can be used as heat insulation and heat preservation materials.

4. Tight organization, and small pores, can be used as a good filter material. Due to the compact density of felt, the performance is more stable and can be punched to produce various felt parts.

5. Good abrasion resistance, can be used as polishing material.

6. Elasticity, so by the principle of shrinkage bonding. After bonding by shrinkage, it can be used separately by the size and specification of density.

7. Felt has good stretchability and can be used for leather rolling belt and paper absorbing belt with the specified length.

8. Felt has good warmth and can be made into various specifications of felt insoles.

9. Felt has moisture retention and elasticity and can be made into automobile door and window seals, central door and window seals. It does not use warp knitting, so good filtration can be used for oil absorption, ship oil barrels under most of the use of felt, to keep the ship clean. Felt packing machine parts with high whiteness, good anti-vibration performance, and noise elimination. According to the size of felt can modulate the sound of musical instruments.

Difficult to maintain

Cleaning felt product is a bit difficult. Clothes made of felt cannot be thrown into the washing machine, and they tend to shrink when put into warm or hot water. And also water-soaked wool felt may be deformed in the washing machine. Therefore, garment manufacturers will recommend dry cleaning or hand washing.

Pest attraction

Felt is the raw material of wool, which is susceptible to insect pests, such as moths. The main reason is that wool tends to absorb sweat or moisture from the body, which is the main source of water for moths. When the pests feed on the clothes, they cause some holes in the clothes and thus damage the clothes. This is the time when you need to use mothballs and other pest prevention stuff to protect the clothes.

Rough to the touch

It feels stiff to the hand and tends to produce some lint because felt is pressed in the manufacture rather than woven like other fabrics.

No stretch

Unlike other elastic fabrics, once the felt is stretched out, unfortunately, there is no way to restore it to its original shape and size.

1. Wool felt

Wool felt is made of wool, the oldest form of weaving in human history, and it can be used to make all kinds of handicrafts, such as dolls, dolls, groceries, jewelry, accessories and felting. Wool felting is rich in color, simple to make, and the tools used are not complicated, so this material is very popular in Europe, America, Japan and other countries. Wool felt handicraft is still a new craft category in China.

2. Acrylic felt

Acrylic felt of the entire felt pile surface fluffy, pile density uniform, felt elasticity moderate, strong sense of standing hair. As the product is shaped, woven in any external conditions, the product is washed, the size and pile almost no change. The size of the whole warp knitting felt is very unstable. To produce a certain specification of products, the corresponding size and weight are under the condition of post-processing (such as back sizing, etc.), but after washing, it is likely to return to the original state, and because the wool yarn is not involved in the formation of the loop, the rate of falling wool is much higher than that of warp knitting products, and is not resistant to washing. Click here to learn what is acrylic fabric.

3. Fur felt

Felt cloth has soft felt cloth, hard felt cloth, thin felt cloth and thick. Because of its excellent durability and high ductility become very useful, in this is to be divided according to the density, different density application areas are also different.

4. Rayon Felt

Rayon felts are commonly used in industrial and medical applications and have the hydrophilic properties of wool felts. One of the main advantages of rayon felts is the ability to mold the textile into a variety of insulating products, but like all synthetic textile fibers, rayon is a non-biodegradable contaminant.

5. Pressed Felt

Pressed felts are made by interlacing fibers through a combination of mechanical work, chemical action, moisture and heat. Felt can be composed of one or more types of fibers, wool, reprocessed wool and reused wool, with or without animal, vegetable and synthetic fibers.

6. Needle felt

Needle felt is a fine fiber cloth made by needling machine, using fibers arranged in a staggered pattern with evenly distributed voids. The main raw materials are: wool, cashmere, chemical fiber, or polyester chemical fiber, polypropylene fiber, colored fiber, viscose fiber, acrylic fiber, etc... Knowledge about needled punched nonwoven fabric.

Nonwoven fabric is a fabric that is formed without spinning and weaving, but simply by fixed or randomly arranging textile short fibers or filaments to form a fiber network structure, which is then reinforced by mechanical, thermal or chemical methods. Non woven fabric burns non-toxic and odorless, and there is no residual material. Its characteristics ensure that nonwovens are environmentally friendly and, crucially, suitable for washing. Nonwovens break through the traditional textile principle and are characterized by short process flow, fast production, high yield, low cost, versatility and many sources of raw materials.

According to the previous article, felt fabric is made of natural wool, using the shrinkage characteristics of wool by machine processing bonding. Wool itself is also a biodegradable, non-toxic, eco-friendly material. It is also a biodegradable and eco-friendly material. It is flexible and can be used as a material for shockproof, sealing, padding and elastic steel wire knitting backing. Good bonding properties, not easy to loose, wool felt can be punched and cut into various shapes of parts. Wool felts can be used as heat insulation and thermal insulation materials. Wool felt is a good filtering material with tight organization and small pores. Good abrasion resistance, wool felt can be used as polishing material.

Above is the introduction of felt fabric. Wondering where to buy felt fabric, now choose high-quality felt fabric to complete your DIY project. You are welcome to Contact G&F GROUP INC., we have 20 years of wholesale experience and a professional service team, with the purpose of modern enterprise management of honesty, truth-seeking, and innovation, with the business philosophy of survival by quality, development by reputation, and satisfaction of customers as the root, we seek development together with customers.

Please send the detailed requirements of fabrics to our email: [email protected]. For example, the quantity, composition, color, usage of fabrics, etc...

All Rights Reserved: https://www.groupgf.com/info-detail/felt-fabric

Copyright Notice: This is an original (translated) article from G&F Group Inc., please indicate the source from G&F Group Inc.. If there is any infringement, please contact us first.

Nonwovens in daily life ----- automotive

Nonwovens in daily life ----- automotive

What is SAP – superabsorbent polymers

What is SAP – superabsorbent polymers

The Future of Global Nonwoven Wipes to 2029

The Future of Global Nonwoven Wipes to 2029

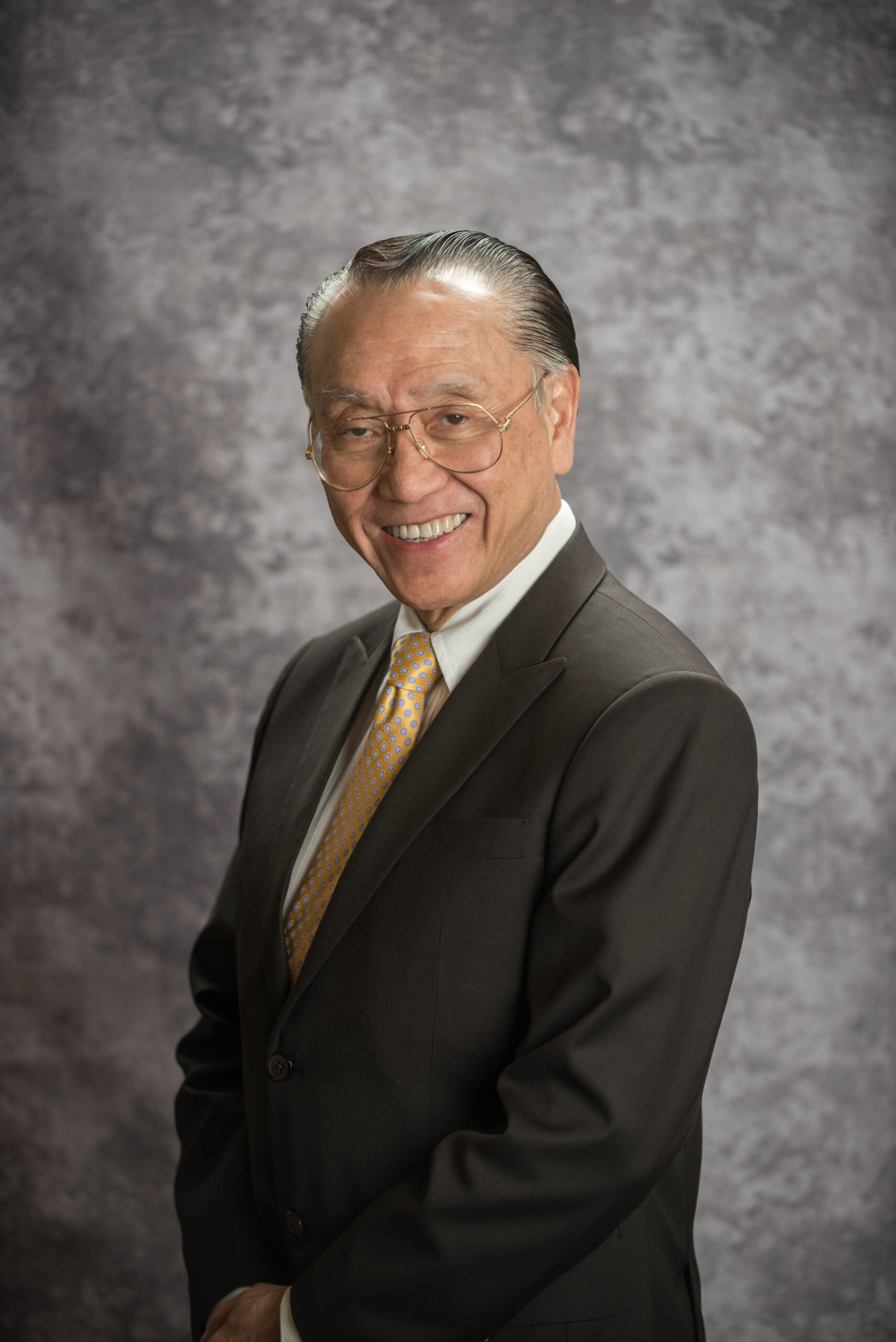

C.K. Wong, Nonwovens Industry Pioneer, Passes Away in Hong Kong

C.K. Wong, Nonwovens Industry Pioneer, Passes Away in Hong Kong