Definition:

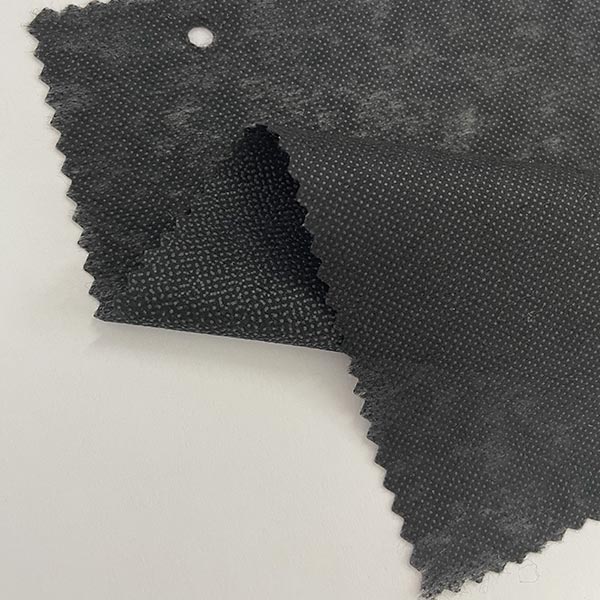

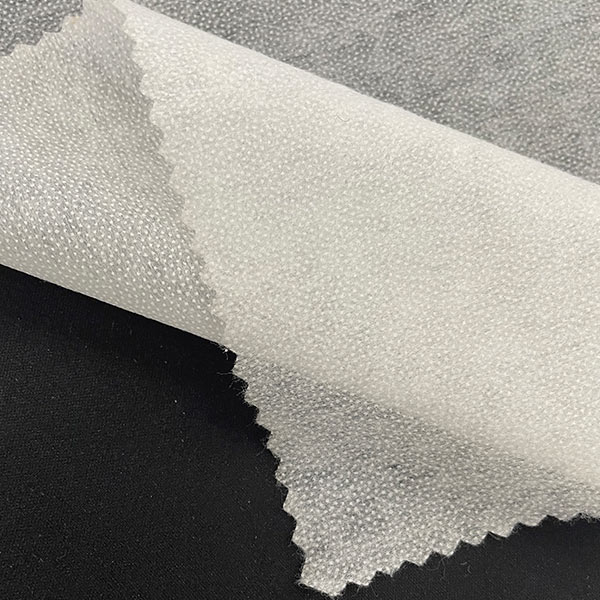

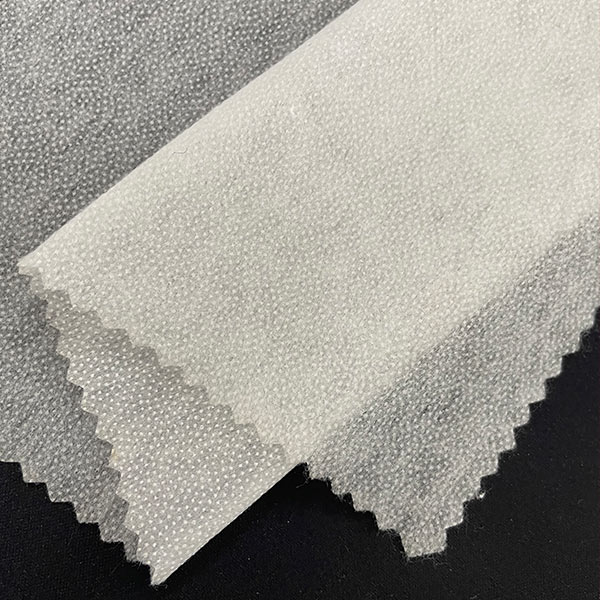

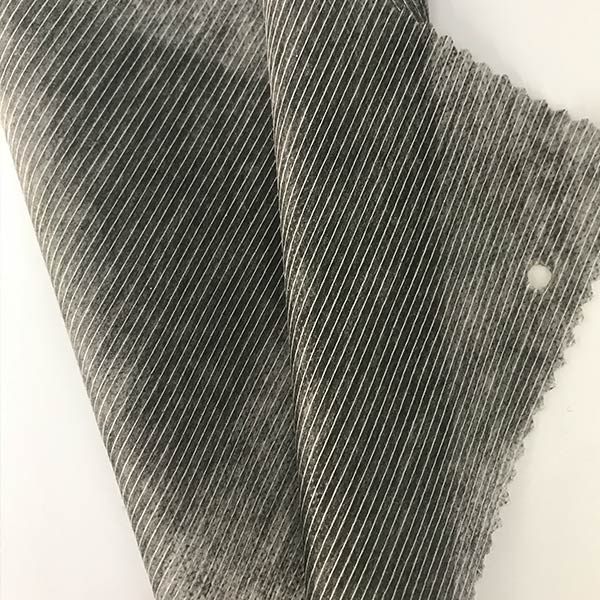

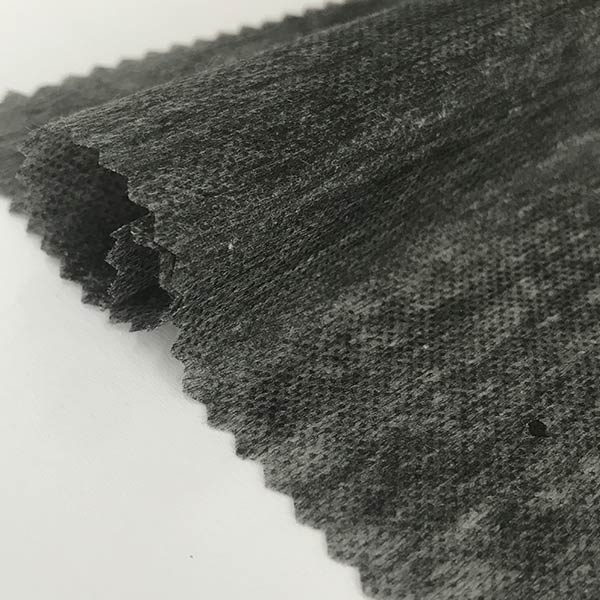

Nonwoven fusible interlining is a hot rolled nonwoven fabric using polyester and nylon fiber blend as the base fabric. After PES powder bonding coating and other special processing technology to become a lining, with a soft feel and good breathability.

Detailed Product Specifications And Parameters:

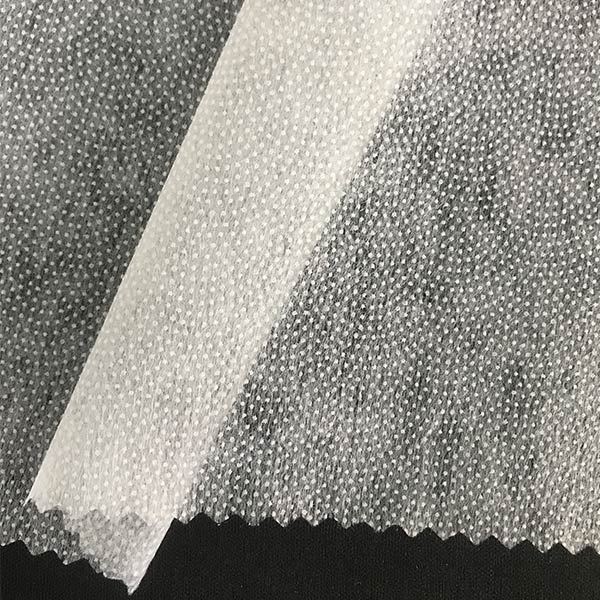

Detailed specification: 8G rubber powder on the backing fabric made of polyester and nylon fiber blend, using PES pulp dot coating process.

| Composition: | 50%Polyester+50%Nylon |

| Grammage range: | Backing fabric: 25G. Coating: 10G. |

| Width range: | Within 2 meters |

| Color: | White, black, grey, extra white |

| MOQ: | 1000m |

| Feeling hardness: | Regular Feeling |

| Packing quantity: | According to customer requirements |

| Packing material: | PE transparent plastic bag |

| Loading quantity: |

20GT/40HQ |

| Customs code: | 5603911090; 5603921090; 5603931090. |

| Glue powder: | PA |

| Pressing temperature: |

120-130 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: |

12-15S |

Features:

Certificate of Non Woven Interlining

Introduction To The Production Process Of Backing Fabric:

The polyester staple fiber or other fibers are fully broken up and mixed by the open cotton process. After combing and spreading, the backing is hot-rolled by hot-rolling sticks to complete the production of backing fabric.

Process Description:

Base cloth production: 50% polyester and 50% nylon staple fiber through the cotton opening process to fully break up the fiber, mixed, and then after carding, laying the network, by hot-rolling stick hot-rolling molding to complete the production of the base cloth. Coating glue: PES pulp point method is a certain particle size of PES hot-melt adhesive powder and water thickener, etc. in accordance with a certain formula and process first mixed into a certain viscosity of stable pulp, and then draw on the round screen printing process, through the pulp supply system, the pulp containing hot melt adhesive in the squeegee pressure through the finely designed circular mesh inner hole in the form of a dot transfer to the bottom cloth, in the drying room to evaporate water hot melt adhesive melt cooling, and then sub-roll packaging.

Product Picture Show

Application Description:

Nonwoven fusible interlining has a soft feel and strong bonding characteristics, suitable for all kinds of light and smooth fabrics, mainly used in all kinds of high-end clothing, as well as garments in specific parts.

You May Also Like:

|

|

|

| QD7025 Non Woven Double Dot Interlining | D7025 Double Dot Fusible Interlining | C7025 Nonwoven Dot Paste Fusible Interlining |