Product Definition:

Tricot knitted fusible interlining is made of viscose and polyester filament as raw materials, woven warp knitted fabric as the backing, and through the brushing, shaping, gluing process, with better shape retention and elasticity, mainly used for the interlining of suit products.

Detailed Product Specifications:

| Base fabric composition: | polyester 50% + viscose 50% |

| Backing fabric process: | spun |

| Item: | F8140A |

| Weight: | 140GSM |

| Powder type: | PA powder |

| Gluing process: | powder point |

| Feel hardness: | conventional |

| Width range: | 150cm |

| Color: | white/black |

| Order quantity: | 3000m |

| Packing quantity: |

50-100m/roll |

| Packaging material: |

plastic bag |

| Customs code: |

5901*** |

| PA glue powder pressing temperature: |

125-150 ℃ |

| PA glue powder pressing pressure: |

2.0-4.0 |

| PA glue powder pressing time: |

15-18 |

| Peel strength: | 12N-15N |

Product Features:

Certificate of Woven Interlining

Introduction To The Production Process:

Base fabric weaving - Fabric pile - Fabric shaping - Gluing and coating - Finished products are packed in rolls

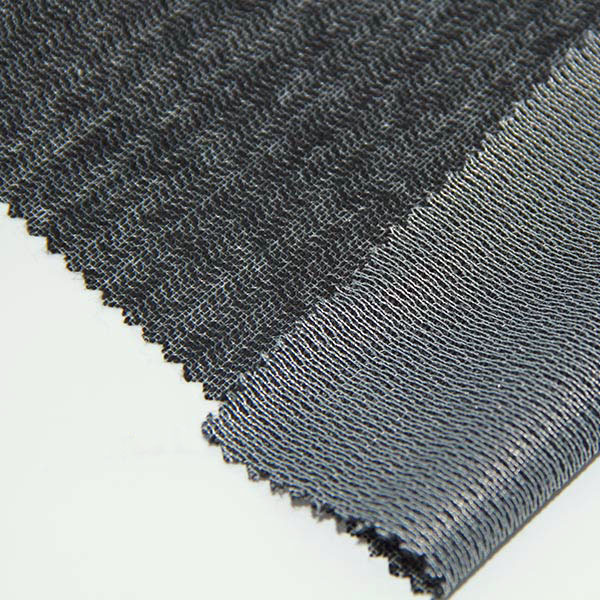

Product Picture Show

Product Applications:

F8140HA Tricot knitted fusible interlining is made with PA gum powder, which has excellent dry cleaning resistance and a harder feel compared to conventional products and can meet the needs of professional formal wear and suit production with higher requirements for external shape and elasticity. It can meet the demand for professional formal wear and suits with higher requirements for external shape and elasticity.

You May Also Like: