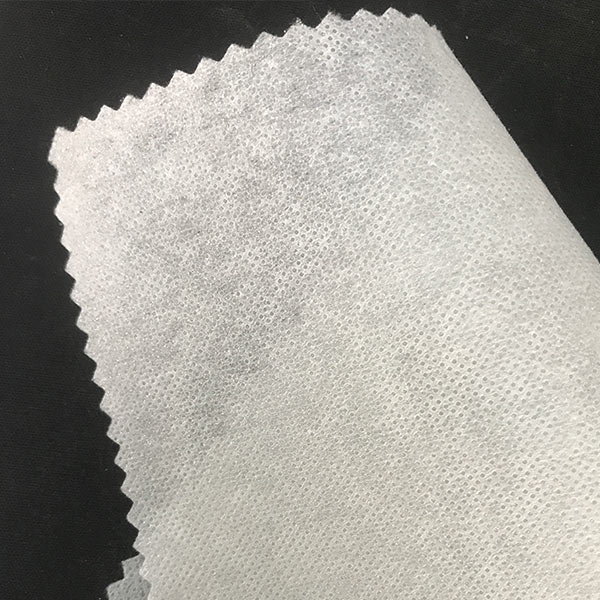

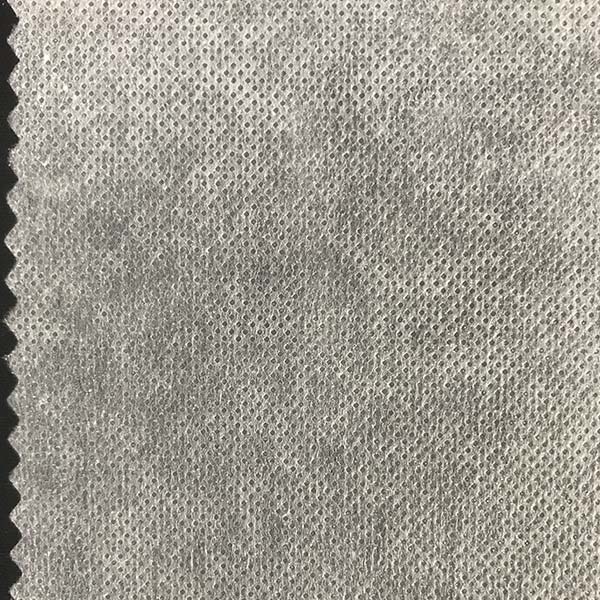

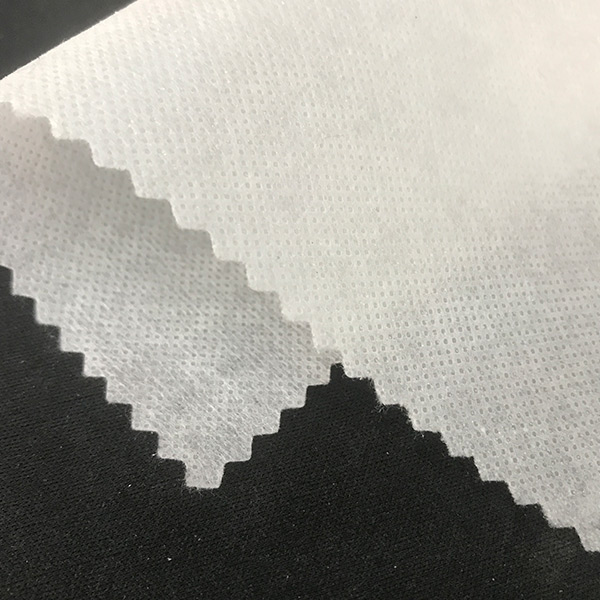

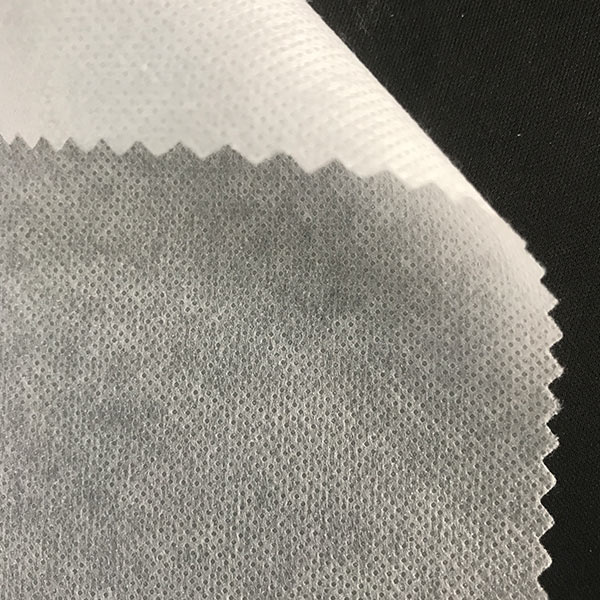

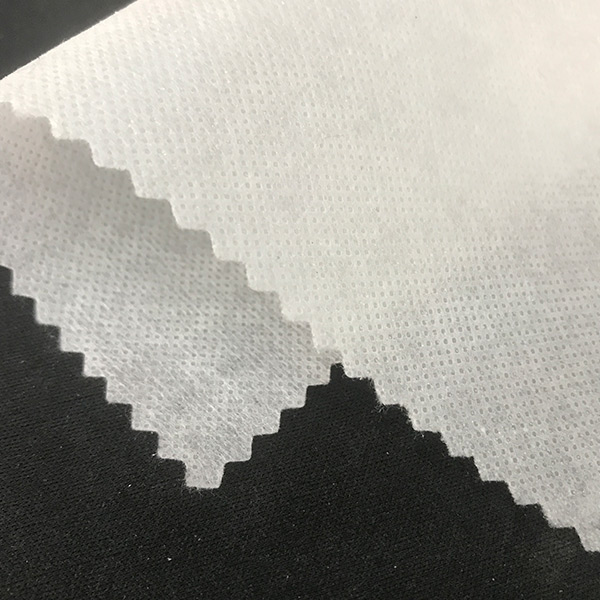

Compared with impregnated nonwoven interlining, the most important feature of thermal bonding nonwoven fabric is to replace the impregnation bonding process with a hot roll bonding process, adding hot melt adhesive fibers to polyester fibers, melting the hot melt adhesive, and bonding the polyester fibers through the hot roll process to make a nonwoven backing fabric, and then applying LDPE or EVA powder coating according to demand. The glue application process can be chosen from powder dispensing, or flat glue after hot pressing. The non-woven base fabric produced has a softer feel and uses very few chemical additives, making it more environmentally friendly and widely used for various types of garment lining or temporary bonding.

Detailed specifications: 15G LDPE or EVA adhesive powder on 45G hot rolled process backing, generally using a dusting of flat glue sizing process.

| Composition: | 100% polyester chemical fiber |

| Grammage range: | Base fabric: 25G; Coating: 12G |

| Width range: | within 2 meters |

| Color: | white, black |

| MOQ: | 5000m |

| Feeling hardness: | regular feeling |

| Packing quantity: | according to customer requirements |

| Packing material: | PE transparent plastic bag |

| Loading quantity: | 20GT/40HQ |

| Customs code: | 5603911090; 5603921090; 5603931090. |

| Glue powder: |

LDPE/EVA |

| LDPE pressing temperature: |

130-140 degrees |

| Pressure: |

2-2.5kg/cm2 |

| Time: |

12-15S |

| EVA pressing temperature: |

100-110 degrees |

| Pressure: |

0.1-0.5kg/cm2 |

| Time: | 10-12S |

Backing production: The polyester staple fiber, or and other fibers through the open cotton process to fully break up the fiber, dot fusing mixed, and then after carding, laying the network, by hot rolling stick hot roll forming to complete the production of the base fabric. Glue powder coating: The hot melt adhesive resin is ground into a certain particle size of hot melt the adhesive powder, then the hot melt adhesive powder is scattered on the top surface of the backing as evenly as possible, then the powder is hot molten in the drying room, flat fusing on the top surface of the backing and then cooled, or the adhesive powder is flattened by hot pressing roller, the finished product is hot rolled nonwoven interlining.

Thermobonding non-woven interlining-850SF is a low-cost, easy to use, thick and soft to the touch, used for all kinds of thick fabric garments, or for temporary bonding, low-temperature bonding purposes.

|

|

|

| 850SF Thermobonding Nonwoven Interlining | 830SF Thermal Bonded Interlining | 720SF Thermobonding Interlining |