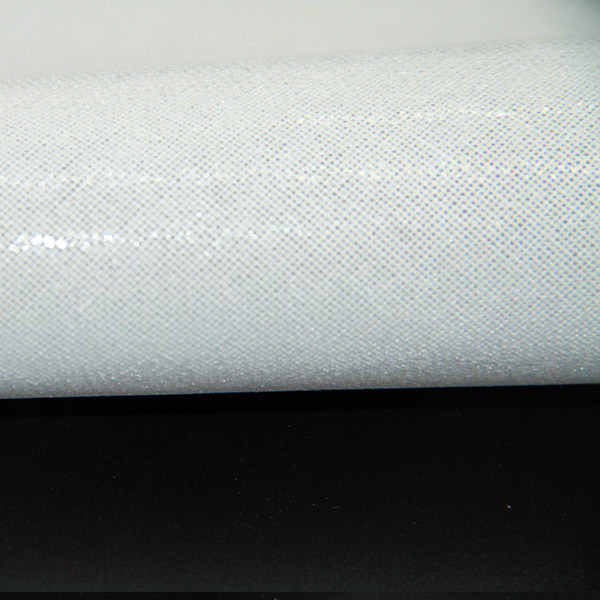

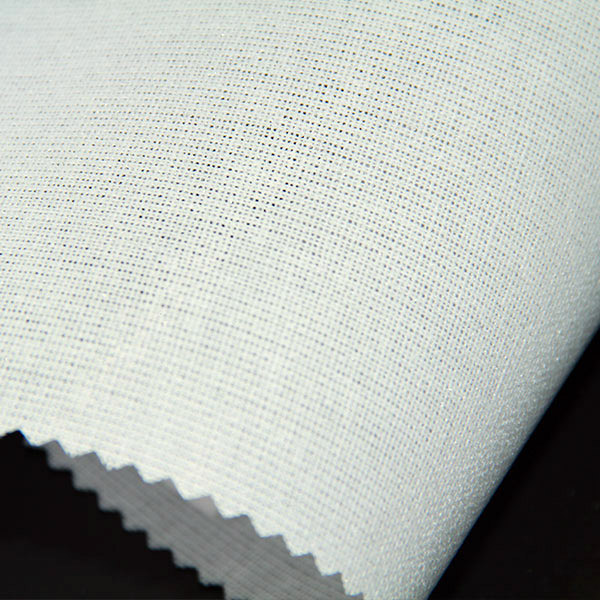

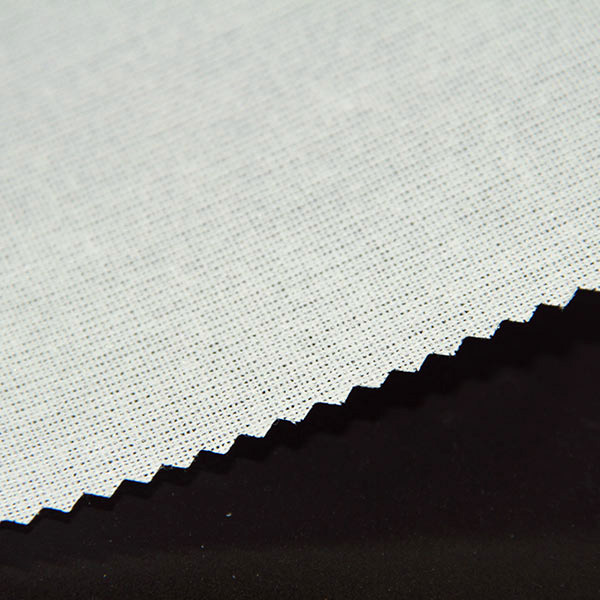

Poly interlining for shirt collar is generally woven from polyester or polyester-cotton yarn, bleached, dyed, and finished with resin according to the required hardness and color, and finally, the corresponding rubber powder is sprinkled on the surface of the cloth to complete the coating, and the produced interlining product is polyester collar interlining.

| Base fabric composition: | polyester, polyester + cotton |

| Item: | 1038HHF |

| Yarn count information: | 10*10S/36*34S |

| Backing fabric process: | woven |

| Grammage: | 60g-200g |

| Powder type: | HDPE, LDPE |

| Gum powder weight: | 25-35 |

| Gluing process: | coating |

| Feeling hardness: | hardened HH |

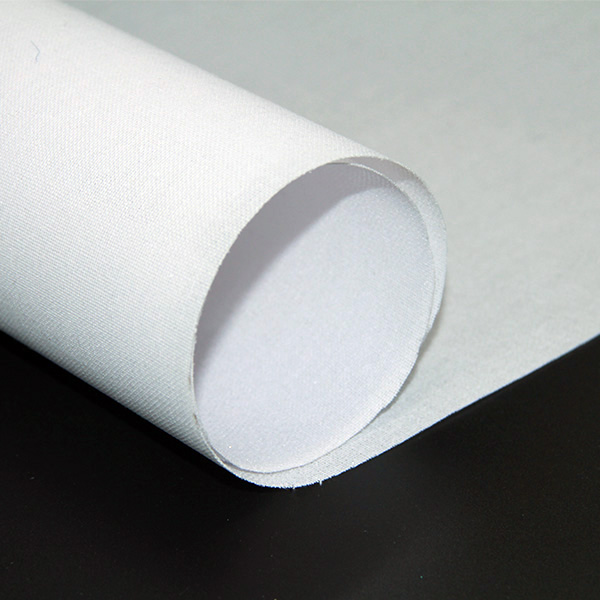

| Width range: | 90cm -112cm |

| Color: | white, dyed |

| Order quantity: | 3000M or more |

| Packing quantity: | 100M or as required |

| Packing material: |

woven bag |

| Loading quantity. | 20/40 feet container |

| Customs code: | 59019091.9/59019092.9 |

| HDPE glue powder pressing temperature: | 175 degrees |

| HDPE glue powder pressing pressure: | 3.5kg/cm2 |

| HDPE glue powder pressing time: | 15 seconds or more |

| HDPE peel strength: |

≥ 18N/5*10cm |

| LDPE glue powder pressing temperature: |

165 degrees |

| LDPE glue powder pressing pressure: |

3.5kg/cm2 |

| LDPE glue powder pressing time: |

15 seconds or more |

| LDPE peel strength: |

≥10N/5*10cm |

Spinning, embroidery weaving, weaving blank desizing, rinsing, drying, adding resin + setting, coating, inspection, rewinding, packing, storage.

Poly interlining for shirt collars is used for shirts, hats, and other industrial products that require reasonable cost and high hardness.