Taffeta Fabric is a light, crisp, and smooth plain fabric made of silk or copper ammonium rayon. The word is derived from the Persian word meaning "twisted weave". It is considered a "premium" fabric for ball gowns, wedding dresses, and upholstery fabrics such as curtains or wallpaper. It is also widely used in the manufacture of corsets and bodices and has superiority over other fabrics for shaping.

Taffeta, also known as taffeta silk, is a kind of cooked woven high-grade silk fabric with a plain weave. The warp yarn is made of double twist silk, and the weft silk is made of single twist silk in parallel, with the plain weave organization as the ground. The density of the weave is high, and it is one of the closest varieties of silk weaving.

As the product is a full silk high-grade fabric, the process is long and complicated, and the weaving requirements are high.

Requirements.

Despite the simple structure of the fabric, each process is quite strict, so careful design and operation are quite important. The main process flow:

Warp direction: raw material picking - twisting - merging - twisting - self-setting - twisting - dyeing - winding - warping - weaving

Weft direction: raw material picking - winding - twisting - twisting - twisting - self-setting - twisting - dyeing - winding - weft winding - weaving

After the taffeta fabric is finished weaving, it needs to go through the finishing process in the finished product workshop, such as initial inspection, re-inspection, sampling, finishing, packaging, etc. and can be sold only after passing the commercial inspection. The light is used in the inspection of the north light. The inspection is carried out according to the national or seal sample standards. The finishing process includes picking and staining. The finishing process should be clean, and the defects of the weaving should be perfected as far as possible. Weeding should be free of watermarks and drop crease marks. When packing the tube rolls, they should be flat and without wrinkle marks and packed in boxes strictly according to the varieties and color numbers.

The silk surface of taffeta is fine and smooth, flat and beautiful, with good luster, tightly woven and stiff to the touch. However, it is easy to produce permanent creases after folding. Therefore, it is not suitable for folding and heavy pressure, commonly used in roll packaging. There are many varieties of taffeta, according to the raw materials used: silk taffeta, double palace silk taffeta, silk-cotton interwoven taffeta, silk weft taffeta, rayon taffeta. Mainly used as women's spring and autumn clothing, festival dresses, down jacket fabrics, etc...

According to the raw material used is divided into silk taffeta, double palace silk taffeta, silk-cotton interwoven taffeta, silk weft taffeta, rayon taffeta, polyester silk taffeta, etc.

According to the weaving process: plain taffeta, shiny taffeta, striped taffeta, jacquard taffeta, etc.

Plain taffeta is woven with a single color of dyed and cooked silk. Flash taffeta uses the different colors of warp and weft yarns to form a flash effect after weaving. The striped taffeta is made by using different color warp and connecting yarns arranged at regular intervals to form a striped effect after weaving. Jacquard taffeta, known as flower taffeta, is woven on the plain ground of plain taffeta with a satin warp pattern.

Polyester taffeta is a kind of all-polyester thin fabric with specifications of 190T, 250T, etc. The general market price is 2-2.5 yuan/meter.

Polyester taffeta is suitable for jackets, umbrellas, car covers, sportswear, marine umbrella, handbag, luggage, sleeping bag, tent, artificial flower, shower curtains, tablecloths, chair covers, and other kinds of high-grade clothing lining.

170T, 180T, 190T, 210T, 230T, 240T, 260T, and 300T (Poly100%) can be coated with PA, PU, PVC, gold, silver, white, red, black, super water repellent and a series of other post-processing treatments.

This is the end of the introduction of Taffeta Fabric, for more information about Taffeta and our advantages, certificates, etc., please feel free to contact us.

All Rights Reserved: https://www.groupgf.com/info-detail/taffeta-fabric

Copyright Notice: This is an original (translated) article from G&F Group Inc., please indicate the source from G&F Group Inc. If there is any infringement, please contact us first.

Nonwovens in daily life ----- automotive

Nonwovens in daily life ----- automotive

What is SAP – superabsorbent polymers

What is SAP – superabsorbent polymers

The Future of Global Nonwoven Wipes to 2029

The Future of Global Nonwoven Wipes to 2029

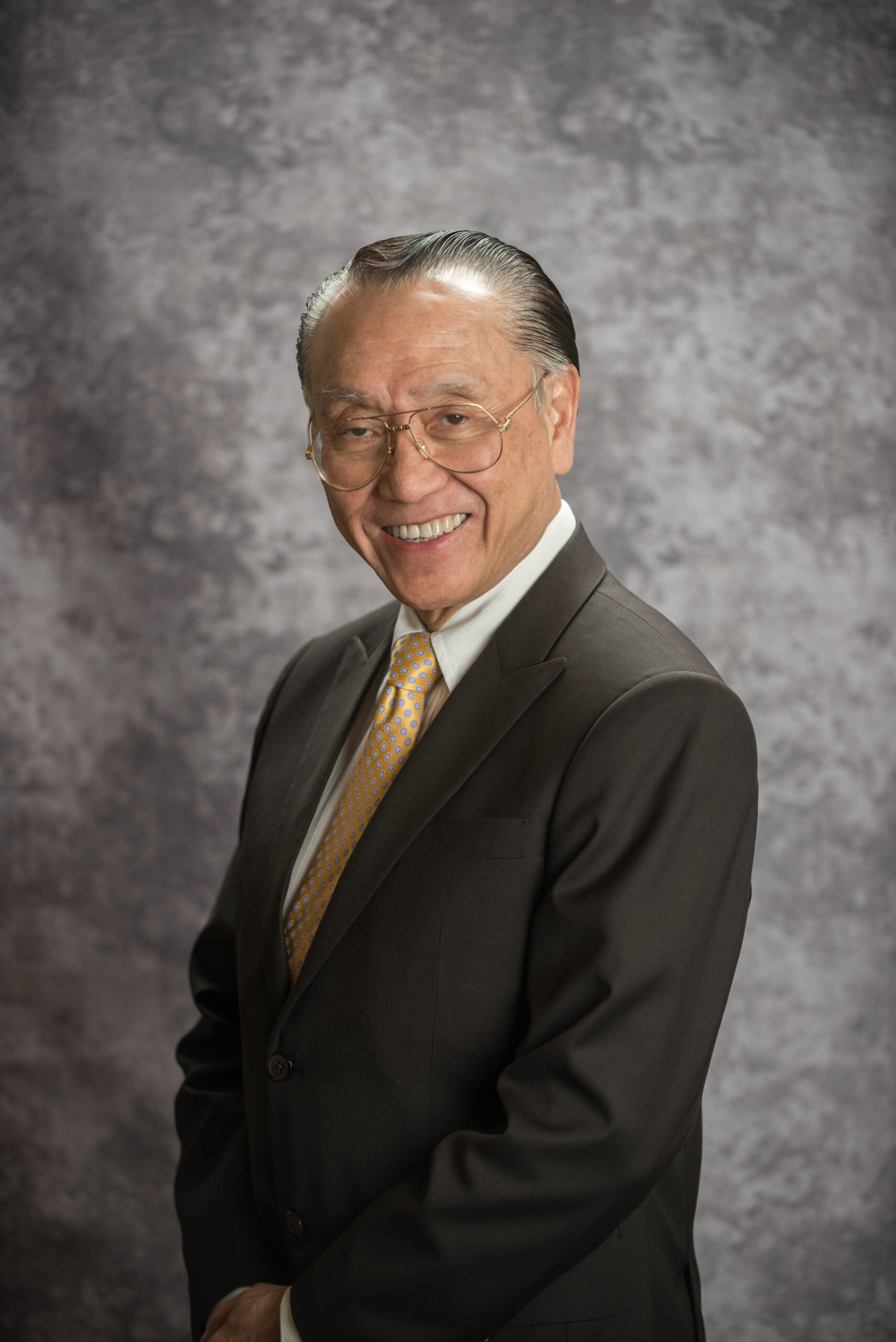

C.K. Wong, Nonwovens Industry Pioneer, Passes Away in Hong Kong

C.K. Wong, Nonwovens Industry Pioneer, Passes Away in Hong Kong